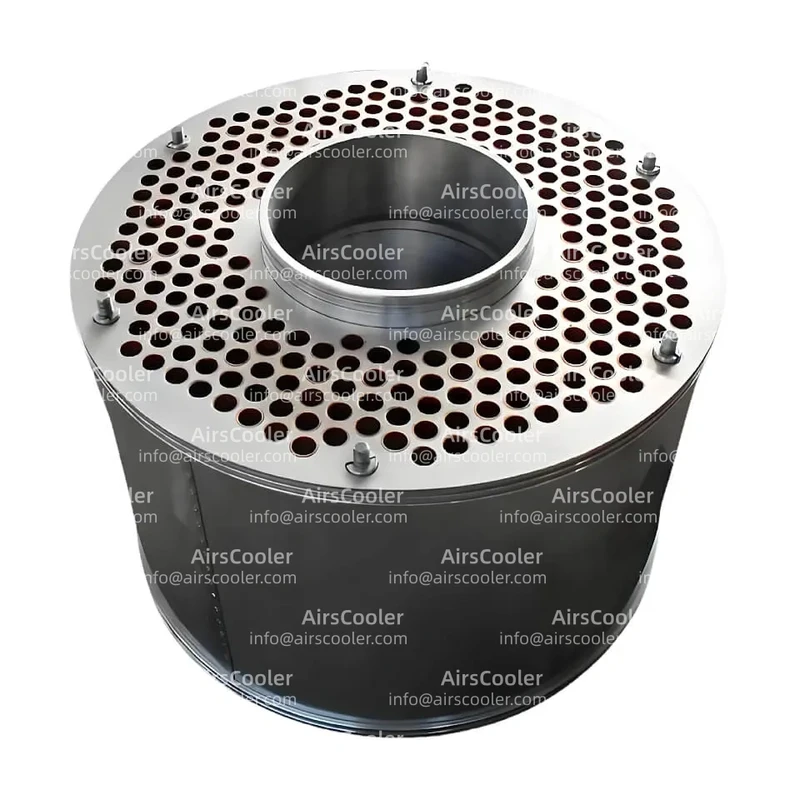

Centac Cooler 5C

Comprehensive technical breakdown and practical implementation of Fete Vessel's advanced industrial cooling solution for centrifugal compressors.

1. Product Overview: Core module for Efficient Heat Exchange

The Centac Cooler 5C serves as the critical temperature control module in industrial centrifugal air compressor system setups. configured based on multi-stage compression thermodynamics, it enhances heat transfer overall efficiency between air and cooling media to help ensure stable compressor operation under high-efficiency conditions. This modular cooler integrates with Centac series compressors' three-stage compression units, working alongside diffusers and sealing system setups to form a complete thermal management offering.

1.1 Structural Composition and Operating Principle

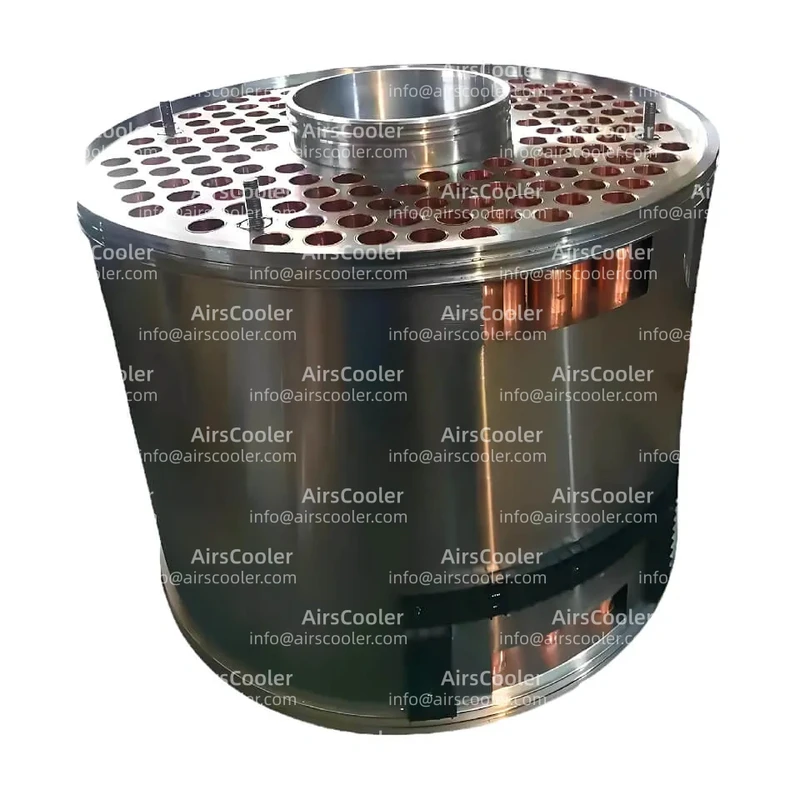

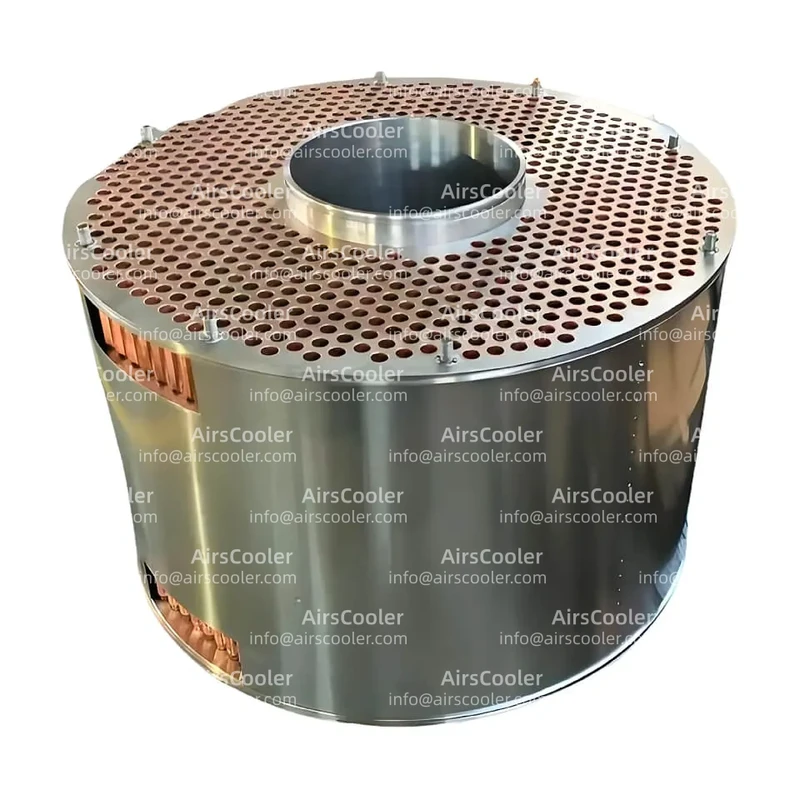

The cooler features a multi-tube flow path system setup with copper tube/stainless steel cover composite construction. Air flows through tubes while cooling water circulates externally, creating counter-flow heat exchange channels. Wave-shaped fins increase air-side heat transfer area by 30+%. Water distributes evenly via top headers while air enters from the bottom, forming spiral upward flow guided by diffusers for optimal turbulent contact. This design minimizes air temperature from 150-180°C post-compression to 40-50°C with 75%+ cooling overall efficiency.

1.2 operational performance Specifications

| Parameter | Specification |

|---|---|

| Flow Range | Compatible with Centac C250/350 units, handles 50-74m³/min |

| pressure loss | Air side ≤0.02MPa, Water side ≤0.05MPa |

| Materials | B10 CuNi alloy tubes, 316L stainless steel covers, optional Heresite coating (C5M grade) |

| Connections | DN50 flanged water inlet, DN80 welded air outlet |

2. Technical Features with Data-Driven Analysis

2.1 Enhanced Heat Transfer Technology

Wave-Shaped Fins: 0.15mm aluminum fins with 12mm height, 2.5mm pitch, anodized surface treatment boosts air-side heat transfer coefficient to 120W/(m²·K).

Fluid Dynamics: CFD-fine-tuned staggered tube arrangement increases turbulence by 40%, with spiral baffles eliminating flow dead zones.

Anti-Corrosion: Heresite P-413 coating passes 2000-hour salt spray testing for marine/chemical environments.

2.2 Automation system setups

Hydraulic Dumping: ±15° adjustable hydraulic flaps with level sensors keep 10-50mm material layer thickness.

Temperature Control: RTD sensors trigger bypass valves when outlet water exceeds 55°C.

Diagnostics: Vibration sensors detect abnormal 120Hz frequencies for early failure warnings.

2.3 Energy overall efficiency Design

Water Optimization: 5-8°C temperature difference minimizes consumption 30% versus conventional designs.

Pressure Recovery: Compressor exhaust drives water circulation pumps to cut motor power.

Modular Expansion: Parallel installation with pressure-balancing valves for smart flow distribution.

3. use case Scenarios and Case Studies

3.1 Industrial use cases

Petrochemical: Cools ethylene cracker compressors keep ≤60°C at 8.5MPa.

Mining: Supports drill rig compressors at 3000m altitude/45°C surrounding with ≤110°C discharge.

Power Generation: Cools gas turbine intake air from 38°C to 18°C, boosting output 3.2%.

3.2 Case Analysis

Case 1: Petrochemical Plant - Solved scaling issues with automatic backflushing, reducing water use to 0.8m³/h and extending compressor runtime.

Case 2: Open-Pit Mine - DXG dust-proof model with 3-stage filtration minimized fouling in 1200μg/m³ PM10 environments.

4. Maintenance Strategy

4.1 Routine Checks

Daily pressure monitoring, shift temperature recording, weekly leak inspections with soap offering.

4.2 Advanced Maintenance

Annual citric acid cleaning, biennial eddy current tube inspection, localized coating repairs.

4.3 Spare Parts

Critical spares: B10 alloy tubes, hydraulic seals, RTD sensors. Implement vibration-based life prediction for proactive replacement.

5. Conclusion

The Centac Cooler 5C redefines industrial thermal management through material science, fluid dynamics, and smart controls. Proven in petrochemical and mining use cases, it extends compressor MTBF while reducing maintenance. With Industry 4.0 integration, digital twin technology will further unlock its potential as a sustainable cooling offering for energy-intensive industries.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler C1000

View Details

View DetailsCentac Cooler C1050

View Details

View DetailsCentac Cooler 2ACII

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.