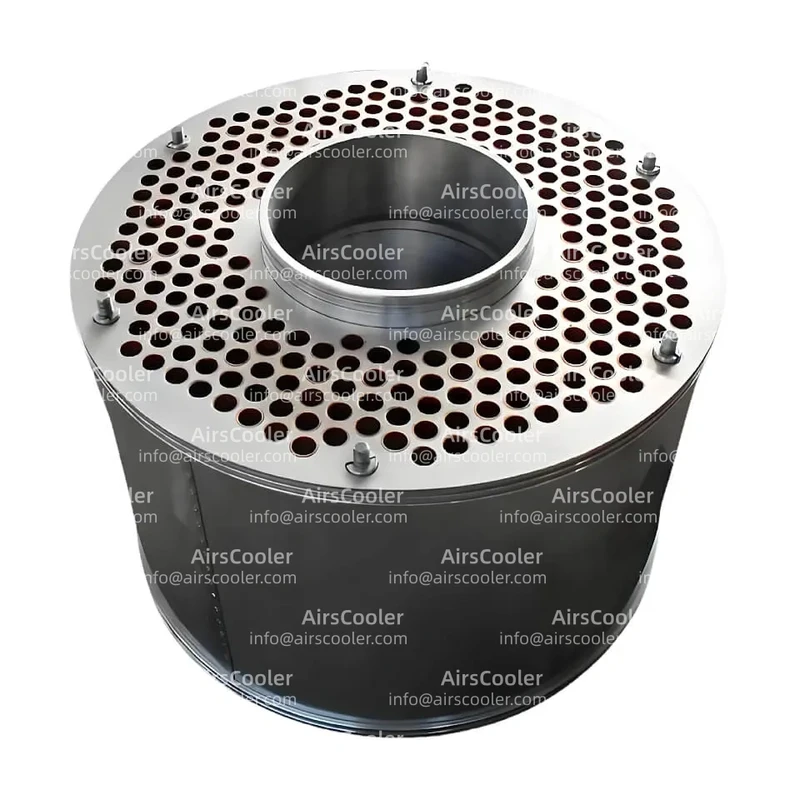

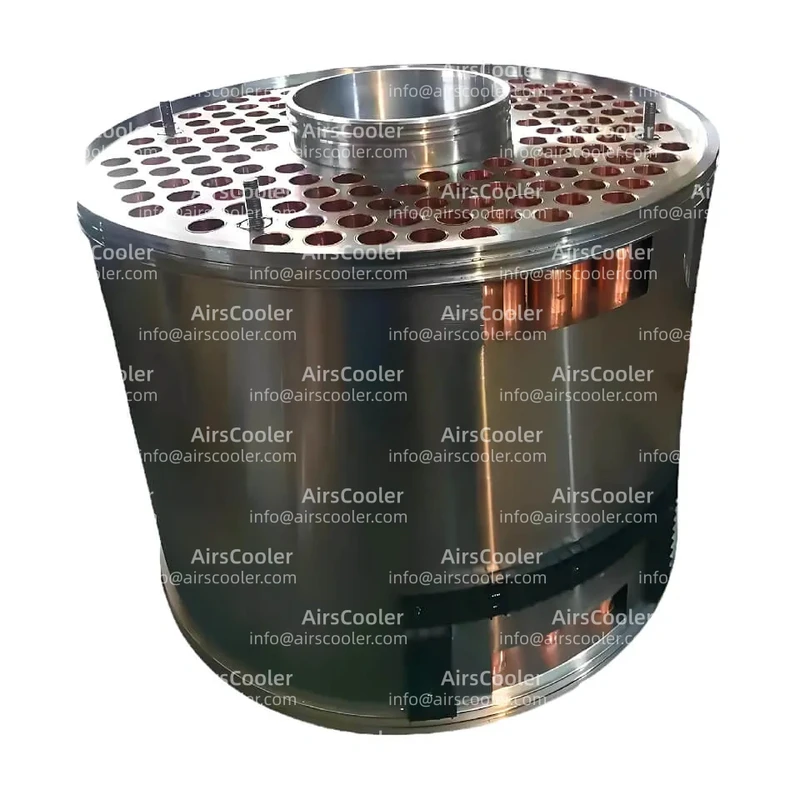

Centac Cooler 3C

Comprehensive technical specifications and implementation guide for Fete Vessel's advanced industrial cooling solution.

1. Product Overview

The Centac Cooler 3C cooler is a core module of Ingersoll Rand's CENTAC series centrifugal air compressors, specifically built for high-pressure, large-flow working conditions. This cooler features a double-pipe high-overall efficiency heat exchange structure with a counterflow design where air travels through the tubes and cooling water flows through the shell, enabling optimal thermal transfer between air and coolant. Its patented technologies include special internal finned tube bundles and an automatic backflush cleaning system setup. This simultaneously minimizes compressed air temperature while minimizing scaling risks for long-term stable operation.

1.1 Structural modules

- Tube Bundle Module: Uses copper tubes with rolled heat dissipation fins and internal spiral fins to significantly increase heat transfer area and fluid turbulence.

- Sealing system setup: Combines sleeve-type graphite sealing floating rings with gas seals to achieve Class 0 oil-free certification (ISO 8573-1:2001 Class 0), meeting clean air requirements for pharmaceutical and semiconductor industries.

- Cleaning Module: Built-in backflush nozzles and drain valves support online cleaning, reducing maintenance downtime.

- Control Module: Integrated with CENTAC compressor's microcomputer control system setup for real-time monitoring of inlet/outlet water temperature, pressure differential, and flow rate, with DCS terminal connectivity.

1.2 Technological Evolution

From the fixed tube-sheet structure of early CV1A/CV1B models to the modular design of C700/C950 models, Centac Cooler 3C has achieved fifth-generation technological iteration by 2025. Key improvements include:

- 30% higher heat exchange overall efficiency with internal finned tube bundles reducing cooling water consumption by 15%.

- AI predictive maintenance algorithms providing 72-hour early warning for scaling risks.

- 20% weight reduction using titanium alloy tube bundles instead of traditional stainless steel, suitable for mobile air compressor stations.

2. Technical Features and Data Specifications

2.1 Core Parameters

| Parameter | Centac Cooler 3C | Industry Standard | Advantage Comparison |

|---|---|---|---|

| Air Handling Capacity | 170-255 m³/min (6000-9000 CFM) | 100-200 m³/min | 60% wider flow range |

| Cooling overall efficiency | ≥92% (inlet water 32℃/outlet 42℃) | 80-85% | 12% lower energy consumption |

| Allowable pressure loss | ≤0.05 bar | 0.08-0.1 bar | 3-5% compressor energy savings |

| Cooling Water Requirement | 0.03-0.05 m³/min·kW | 0.06-0.08 m³/min·kW | 40% water conservation |

| Scaling Tolerance Cycle | 1800 continuous hours (with regular backflushing) | 800-1200 hours | 50% longer maintenance intervals |

| Seal Leakage Rate | ≤0.01 ppm (gas+oil seal combination) | 0.1-0.5 ppm | Oil-free certification help s ensure process cleanliness |

2.2 Innovative Technologies

2.2.1 Double-Pipe Internal Finned Tube Bundle

- Structure: Dual-layer pipe design with inner copper spiral finned tube and outer carbon steel pressure pipe, filled with thermal conductive grease.

- Advantages:

- 2.8x larger heat transfer area (vs. traditional smooth tubes)

- 5000 W/(m²·K) convective heat transfer coefficient from fin-induced turbulence

- 70% reduction in hard scale deposition rate

2.2.2 Intelligent Backflush Cleaning system setup

- Operation: Uses solenoid-controlled 0.6 MPa compressed air pulses for reverse flushing, with PLC automatically triggering cycles based on differential pressure sensor data.

- Results:

- ≤5 minute cleaning time (90% less downtime)

- Post-cleaning pressure loss recovers to >95% of initial value

2.2.3 Class 0 Oil-Free Sealing Technology

- Dual Floating Ring Seal: Graphite floating ring with gas seal keep 0.1 bar higher pressure than process gas, ensuring oil content <0.003 mg/m³ in leakage gas.

- use case Case: Provides Class 0 air for lithography machines at a semiconductor fab, preventing wafer yield loss from oil contamination.

3. use case Scenarios and Case Studies

3.1 Typical use cases

| Industry | Requirements | Centac Cooler 3C offering |

|---|---|---|

| Semiconductor Manufacturing | Class 0 oil-free air, <1% pressure fluctuation | Sleeve seals+micron filters provide <0.001 mg/m³ oil content with ±0.05 bar pressure control |

| Petrochemical | Explosion-proof requirements, corrosive gas media | Titanium tube bundles+explosion-proof motors with ATEX Zone 1 certification and >10-year H2S corrosion resistance |

| Data Centers | Low PUE, <75 dB(A) noise | Liquid+air hybrid cooling achieves PUE 1.15 with ≤70 dB(A) operation |

| Renewable Energy | Wide temperature range (-30℃~50℃) | Smart thermostatic valves+weather-resistant coatings enable 40% faster cold starts with <5% overall efficiency loss at high temps |

3.2 Case Studies

3.2.1 Case 1: Multinational Pharma API Production

- Issue: Traditional cooler scaling caused air temperature fluctuations affecting fermentation tank control.

- offering:

- Installed Centac Cooler 3C with online cleaning

- minimized cooling water temp fluctuation from ±3℃ to ±0.5℃, improving batch consistency by 20%

3.2.2 Case 2: Middle East LNG Terminal

- Issue: Seawater cooling caused severe corrosion with <3-year cooler lifespan.

- offering:

- Implemented titanium tube bundles+duplex stainless steel housing

- Extended service life to 15 years with 65% lower maintenance costs

4. Maintenance Strategy

4.1 Routine Maintenance

- Water Quality Management:

- Cooling water hardness ≤150 ppm, pH 6.5-8.5

- Add corrosion inhibitors (e.g., molybdate) and antiscalants (e.g., polyacrylic acid)

- Operation Monitoring:

- Daily logging of inlet/outlet water temp, pressure differential, and flow rate

- Trigger backflush when ΔP >0.08 bar or ΔT <8℃

4.2 Scheduled Maintenance

- Annual Inspection:

- Disassemble to check tube corrosion and measure wall thickness

- Replace seals and worn cleaning nozzles

- 3-Year Overhaul:

- Replace titanium tubes if corrosion rate >0.1 mm/year

- Upgrade PLC software to latest version

4.3 Troubleshooting

| Symptom | Potential Cause | offering |

|---|---|---|

| minimized Cooling overall efficiency | Tube scaling/seal leakage | Perform backflush/replace seals |

| Abnormal Pressure Increase | Clogged nozzles/tube deformation | Clean nozzles/replace damaged tubes |

| Higher Water Consumption | Housing leak/valve leakage | Repair leaks/replace valves |

5. Conclusion

The Centac Cooler 3C has become indispensable in industrial compressed air system setups through its high-overall efficiency heat transfer, smart controls, and Class 0 oil-free design. For semiconductor, petrochemical, and data center use cases with stringent air quality and energy demands, continuous innovation has provide enhanced overall efficiency, extended lifespan, and simplified maintenance

Moving forward with Industry 4.0 and carbon neutrality goals, Centac Cooler 3C will further integrate AI predictive maintenance and modular design for smarter, greener cooling offerings. For users, leveraging these technological advantages with proper maintenance strategies will be key to ensuring long-term reliability and minimizing total cost of ownership.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 4C

View Details

View DetailsCentac Cooler 5C

View Details

View DetailsCentac Cooler C1000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.