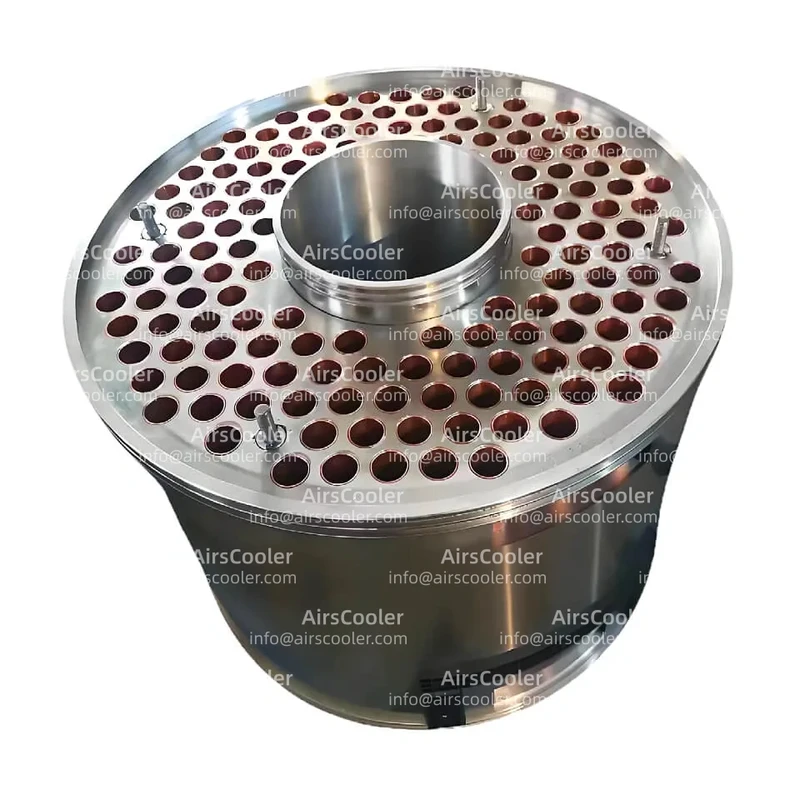

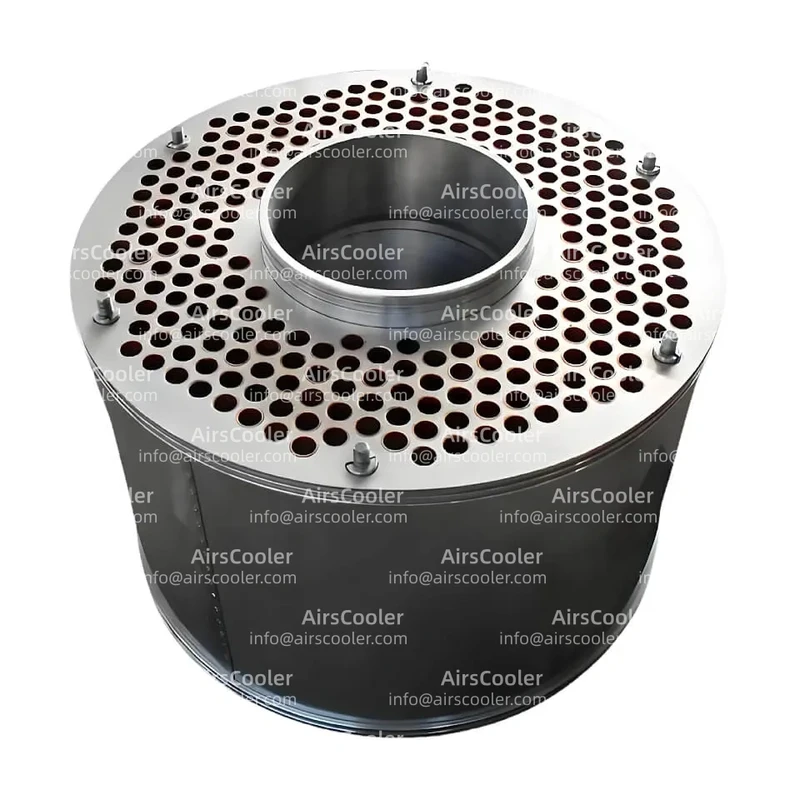

Centac Cooler 2CV

Fete Vessel's advanced cooling solution for industrial centrifugal air compressors

1. Product Overview: Core Temperature Control module for Centrifugal Compressor system setups

The Centac Cooler 2CV is a specialized cooling unit designed by AirsCooler for CENTAC series centrifugal air compressors, serving as a critical heat exchange module in multi-stage compressed air system setups. This cooler efficiently removes heat generated during compression through indirect heat exchange between cooling water and compressed air, ensuring stable operation within flow rates of 720-51,000 m³/h and pressure ranges of 0.7-22.5 kg/cm². Its core functions include:

- Thermal Load Management: Controls outlet temperature below 50°C for high-temperature air (up to 200°C+) from each compression stage, meeting requirements for downstream equipment like dryers and air receivers

- Energy overall efficiency Optimization: minimizes energy consumption in subsequent processes by lowering air temperature, improving mold filling overall efficiency by over 15% in PET blow molding use cases

- system setup Protection: Prevents high-temperature induced seal aging and bearing lubrication failures, extending MTBF (Mean Time Between Failures) beyond 8,000 hours

2. Technical Features and Data Specifications

(1) Structural Innovations and Process Breakthroughs

- Tandem Graphite Seal Floating Ring Technology

- Dual-seal structure: Inner graphite floating ring keep 0.05mm clearance with shaft neck, while outer ring uses 12-15 psig clean air as barrier gas, achieving <1% leakage rate with zero oil contamination

- Temperature resistance: Continuous operation between -40°C to 250°C, suitable for extreme conditions like high-altitude regions (e.g., Qinghai-Tibet Railway)

- High-overall efficiency Sleeve Air Cooler (Patented Technology)

- Heat transfer overall efficiency: Special internal fin design boosts air-side heat transfer coefficient to 120 W/(m²·K), 40% improvement over conventional smooth-tube designs

- Pressure loss control: Air-side pressure loss ≤0.02 bar, keep system setup COP >3.5

- Corrosion resistance: Copper tubes with Heresite coating withstand 100ppm sulfur environments for 10+ year service life

(2) operational performance Parameters and Test Data

| Parameter | Centac Cooler 2CV Specification | Test Conditions |

|---|---|---|

| Air Handling Capacity | 42-62 m³/min (1,500-2,200 CFM) | Inlet pressure 10 barg, temperature 120°C |

| Cooling Water Flow | 8-12 m³/h | Inlet water 32°C, 8°C temperature difference |

| Heat Transfer Coefficient | 115-125 W/(m²·K) | ASHRAE standard test conditions |

| Noise Level | ≤75 dB(A) | Measured at 1m distance |

| Weight | 4,128 kg | Including cooling water system setup |

3. use case Scenarios and Case Studies

(1) Typical use cases

- Pharmaceutical Industry: Combined with 0.5μm air filters for sterile compressed air (-40°C dew point) in fermentation processes, improving penicillin yield by 18% at a Suzhou facility

- Petrochemical Refining: Precise temperature control (±2°C) for catalyst transport in fluidized beds, saving 1,200 tons CO₂ equivalent annually at Sinopec Zhenhai project

- Data Centers: Coupled with immersion cooling for 25°C constant-temperature server air, achieving PUE <1.15 at Tencent Tianjin data center

4. Maintenance Strategy

(1) Preventive Maintenance system setup

- Daily Checks: Ultrasonic flow monitoring (monthly), seal gas pressure verification (weekly)

- Annual Overhaul: Tube bundle cleaning with 0.5% citric acid, graphite ring replacement (biennial), ISO 1217 operational performance testing

5. Technology Evolution and Industry Value

(1) Next-Generation Development

- Phase-Change Cooling: R245fa refrigerant in vacuum tubes targeting 300 W/(m²·K) heat transfer coefficient

- Digital Twin Operation: AI-powered fouling prediction improving maintenance cycles by 40% at Shell Rotterdam refinery

AirsCooler - Industrial Cooling offerings Innovator

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 3C

View Details

View DetailsCentac Cooler 4C

View Details

View DetailsCentac Cooler 5C

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.