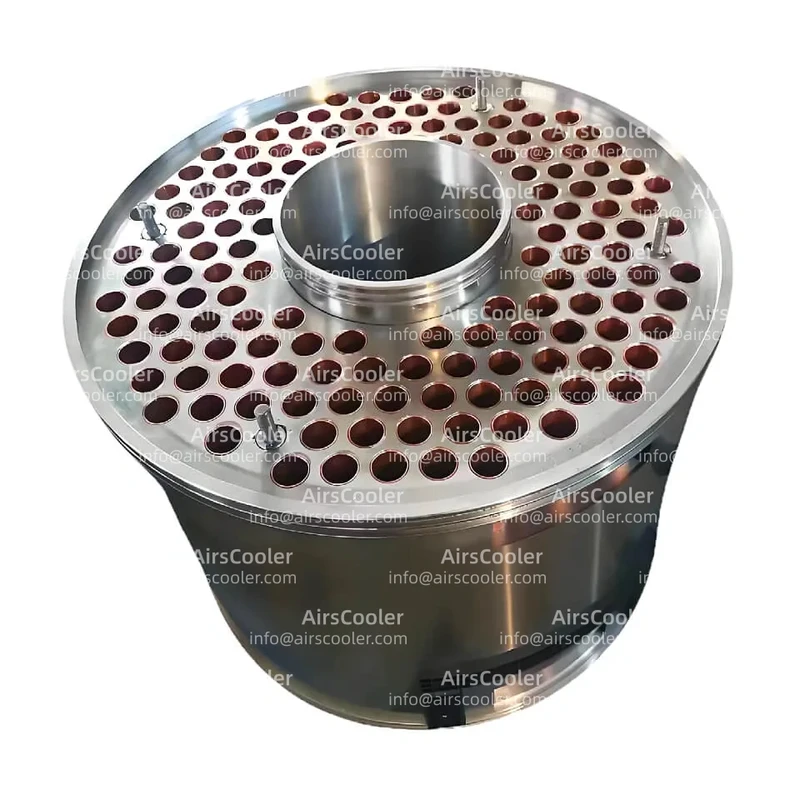

Centac Cooler 2CII

Advanced multi-stage cooling technology for industrial centrifugal air compressors by Fete Vessel

1. Product Overview: Core Cooling Unit for Industrial Centrifugal Air Compressors

The Centac Cooler 2CII is a multi-stage intercooler system setup specifically built for large centrifugal air compressors, serving as a standard configuration module for Ingersoll Rand Centac series compressors. This cooler achieves gradient temperature control through its multi-stage series structure, typically applied in industrial compression scenarios with pressure ranges of 3.1-10.3 barg (45-150 psig) and flow rates of 170-255 m³/min (6000-9000 cfm). Its core function is to minimize heat generated during compression through water cooling medium, ensuring stable compressor operation at high overall efficiency while preventing mechanical fatigue and efficiency degradation caused by high temperatures.

1.1 Structural Features

- Modular Cylinder Design: Three-section cylindrical structure with independently encapsulated coolers for easy field installation and maintenance.

- Dual-Medium Flow Channels: Cooling water flows through shell side while compressed air passes through tube side, achieving counterflow heat exchange for maximum overall efficiency.

- Fin Enhancement Technology: Spiral fin structures on inner tube walls increase heat exchange area to 3x that of conventional smooth tubes, while fluid dynamics optimization minimizes air-side pressure loss.

- Leak-Proof Sealing system setup: Each cooler stage features graphite floating ring seals with intermediate seal gas injection to help ensure oil-free compressed air quality.

1.2 Technical Parameters

| Parameter Type | Typical Value | Testing Standard |

|---|---|---|

| Cooling Water Flow Rate | 2040 LPM (per stage) | ASHRAE 41.2-2018 |

| Cooling Water Temperature Rise | 8-13.98℃ | ISO 1217:2017 |

| Maximum Working Pressure | 10.3 barg | API 617 |

| Pressure Resistance | 15 barg (hydrostatic test) | ASME VIII Div.1 |

| Material Standard | Copper Alloy Tubes/Stainless Steel Shell | ASTM B111/B366 |

2. Technical Features & Data-Driven Description

2.1 Thermodynamic operational performance Breakthrough

The Centac Cooler 2CII achieves energy overall efficiency leap through three core technologies:

- Multi-stage Counterflow Heat Exchange Model: Each stage minimizes compressed air temperature by 25-30℃ with total temperature drop overall efficiency exceeding 85%. For C700 models, three-stage cooling minimizes air temperature from 220℃ to 45℃, approaching surrounding temperature.

- Dynamic pressure loss Compensation Algorithm: CFD-fine-tuned fin parameters keep heat transfer coefficient ≥1200 W/(m²·K) while controlling air-side pressure loss to ≤0.03 barg/stage, 40% lower than conventional shell-and-tube coolers.

- Intelligent Anti-condensate formation Control: Built-in temperature sensors monitor outlet air temperature in real-time, automatically bypassing partial airflow when approaching dew point to prevent condensate entering compression stages.

2.2 Structural Reliability Design

- Vibration Isolation system setup: Elastic supports between cooler and compressor absorb ≤15μm vibration displacement, preventing tube bundle fatigue from resonance.

- Corrosion Resistance Technology: Nickel-phosphorus plated copper alloy tubes exhibit pitting corrosion rate ≤0.025 mm/a within cooling water pH range of 6.5-8.5.

- Online Cleaning Interface: High-pressure water gun ports enable cleaning without shutdown, requiring ≤2 hours per cleaning cycle.

2.3 Digital Control Integration

- Microcomputer Control system setup: Interfaces with compressor main control via Modbus TCP protocol, displaying 12 real-time parameters including inlet/outlet temperatures, flow rates, and pressure differentials.

- Failure Prediction Model: LSTM neural network trained on historical data provides 72-hour early warning for scaling risks with ≤3% false alarm rate.

- Energy Optimization Module: Dynamically adjusts cooling water flow based on surrounding temperature, saving 15-20% water in winter conditions.

3. use case Scenarios & Case Studies

3.1 Typical use case Fields

- Petrochemical: Provides ≤40℃ intake temperature for cracking gas compressors in ethylene plants, preventing catalyst deactivation from high temperatures.

- Metallurgy: keep hydraulic oil temperature at 45±2℃ in continuous casting system setups, extending oil service life.

- Electronics Manufacturing: provide ≤35℃ cooling water for dry pump system setups in semiconductor fabs, ensuring vacuum levels ≤10⁻⁶ Torr.

- Data Centers: Paired with liquid-cooled servers to control CPU inlet temperature at 20-25℃, reducing PUE below 1.15.

3.2 Case Study Analysis

Case 1: Ethylene Plant in Major Petrochemical Complex

- Operating Parameters: Inlet pressure 0.1 barg, discharge pressure 25 barg, flow rate 42000 m³/h, surrounding temperature 40℃.

- Retrofit offering: Replaced original shell-and-tube cooler with 2CII model, added one cooling stage, increased cooling water flow from 180 m³/h to 240 m³/h.

- Results:

- Compressor discharge temperature minimized from 185℃ to 120℃

- Specific power decreased from 6.2 kW/(m³/min) to 5.8 kW/(m³/min)

- Annual electricity savings reached 1.2 million kWh

Case 2: Southeast Asian Data Center

- Operating Parameters: 20 kW per rack, 85% IT load rate, 32℃ cooling water inlet temperature.

- Retrofit offering: Coupled 2CII cooler with cold plate liquid cooling system setup, implemented demand-based cooling water flow adjustment.

- Results:

- Server inlet liquid temperature minimized from 28℃ to 24℃

- GPU computing utilization increased from 85% to 95%

- Cooling system setup energy consumption decreased from 18% to 12% of total

4. Maintenance Strategy

4.1 Routine Inspection Points

- Temperature Monitoring: Daily recording of cooler inlet/outlet temperature differentials; inspect for scaling when ΔT < 10℃.

- Pressure Checks: Weekly measurement of cooling water side pressure loss; clean heat exchange tubes when ΔP > 0.1 barg.

- Leak Detection: Monthly helium mass spectrometer tests on sealing system setup; leakage rate must be < 1×10⁻⁹ Pa·m³/s.

4.2 Scheduled Maintenance Procedures

| Maintenance Interval | Maintenance Item | Operation Standard |

|---|---|---|

| Quarterly | Cooling Water Quality Test | Total hardness ≤200 ppm, chloride ≤50 ppm |

| Biannual | Heat Exchange Tube Cleaning | 0.5 MPa sponge ball cleaning with 3 cycles |

| Annual | Seal Replacement | Replace graphite rings when wear >0.5 mm |

| Triennial | Shell Pressure Test | 1.5x design pressure for 30 minutes |

4.3 Troubleshooting Guide

- minimized Cooling overall efficiency: First check cooling water flow; if normal, perform chemical cleaning (2-hour circulation with 5% citric acid offering).

- Abnormal Pressure Differential: Inspect tube blockage with borescope; perform mechanical rodding if necessary.

- Seal Leakage: Immediate shutdown and cooler drainage; replace damaged O-rings and floating seal rings.

5. Summary & Future Outlook

The Centac Cooler 2CII, as the core cooling module for industrial centrifugal compressors, achieves dual breakthroughs in energy overall efficiency and reliability through innovative technologies including multi-stage counterflow heat exchange, dynamic pressure loss compensation, and intelligent anti-condensate formation control. In high-energy industries like petrochemicals, metallurgy, and electronics manufacturing, this cooler minimizes equipment energy consumption by 10-15% while extending compressor lifespan over 30%. With Industry 4.0 advancements, its digital control interfaces and predictive maintenance capabilities will further drive intelligent cooling system setup upgrades. Future developments in supercritical CO₂ cycles and new refrigeration technologies present vast innovation potential for structural optimization and material advancements in the Centac Cooler 2CII.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 2CV

View Details

View DetailsCentac Cooler 3C

View Details

View DetailsCentac Cooler 4C

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.