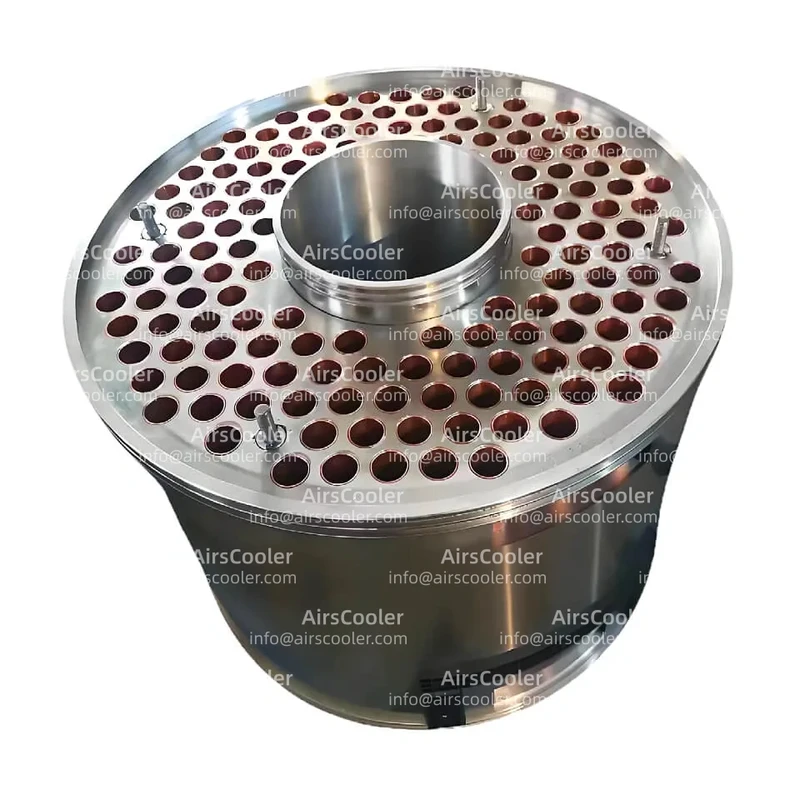

Centac Cooler 2C

Comprehensive technical specifications and practical applications of Fete Vessel's advanced centrifugal air compressor cooling solution.

1. Product Overview: Core module of Air Compressor Thermal Management

The Centac Cooler 2C is a specialized heat exchange device built for centrifugal air compressors, serving as a critical module in the Ingersoll Rand Centac series compressor system setups. Its primary function is to cool high-temperature compressed air to process-required temperature ranges through indirect heat exchange with cooling media (air or water), ensuring equipment stability and improving system setup energy overall efficiency.

Key Features:

- Compact modular design integrated within compressor housing

- Functions as intercooler in multi-stage compression system setups

- Industrial-grade construction for demanding use cases

2. Technical Specifications and operational performance Data

2.1 Structural and Material Innovations

| Feature | Technical Detail | operational performance Benefit |

|---|---|---|

| Multi-tube Flow Design | High-conductivity copper tubes with spiral fins | 40%+ increase in heat exchange overall efficiency |

| Stain Steel Construction | 304 stainless steel frame with Heresite coating | Enhanced corrosion resistance |

| Wave-form Fins | Special turbulence-inducing design | 1.8x convection coefficient improvement |

2.2 Thermodynamic operational performance Parameters

- Cooling overall efficiency: minimizes air temperature from 120°C to below 45°C (62.5% reduction)

- pressure loss: Air side ≤0.02MPa, Water side ≤0.05MPa

- Water Requirements: 0.15-0.25L/s·kW (15% less than conventional designs)

3. Industrial use cases and Case Studies

3.1 Typical use case Scenarios

- Chemical Industry: Provides -40°C dew point air for polyethylene production

- Pharmaceutical: keep air temperature below 25°C for sterile processes

- Electronics: Achieves ≤-70°C dew point for semiconductor manufacturing

3.2 Success Case: Steel Plant Blower system setup

Challenge: Existing cooler showed 30% overall efficiency loss due to scaling, causing 145°C discharge temperatures and shutdowns.

offering: Installation of Centac Cooler 2C with high-pressure cleaning system setup.

Results: 65% temperature reduction rate restored, 120,000kWh annual energy savings, 80% fewer shutdowns.

4. Maintenance and Service Guidelines

4.1 Routine Inspection Checklist

| Check Item | Frequency | Acceptable Range |

|---|---|---|

| Temperature Differential | Daily | >40°C |

| pressure loss | Weekly | <0.03MPa |

| Water Quality | Quarterly | pH 6.5-8.5, ≤200ppm hardness |

4.2 Common Issues and offerings

- minimized overall efficiency: Perform acid cleaning with citric acid offering

- Water Leakage: Replace O-rings or seal gaskets

- High pressure loss: Clean fins and replace air filters

5. Future Development Trends

The Centac Cooler 2C represents AirsCooler's commitment to advanced thermal management offerings. Emerging technologies include:

- Digital twin system setups for predictive maintenance

- Nanofluid cooling media research

- Standardized modular designs for cross-brand compatibility

For optimal operational performance, proper selection, installation and maintenance are essential to maximize the Centac Cooler 2C's technological advantages in industrial use cases.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 2CII

View Details

View DetailsCentac Cooler 2CV

View Details

View DetailsCentac Cooler 3C

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.