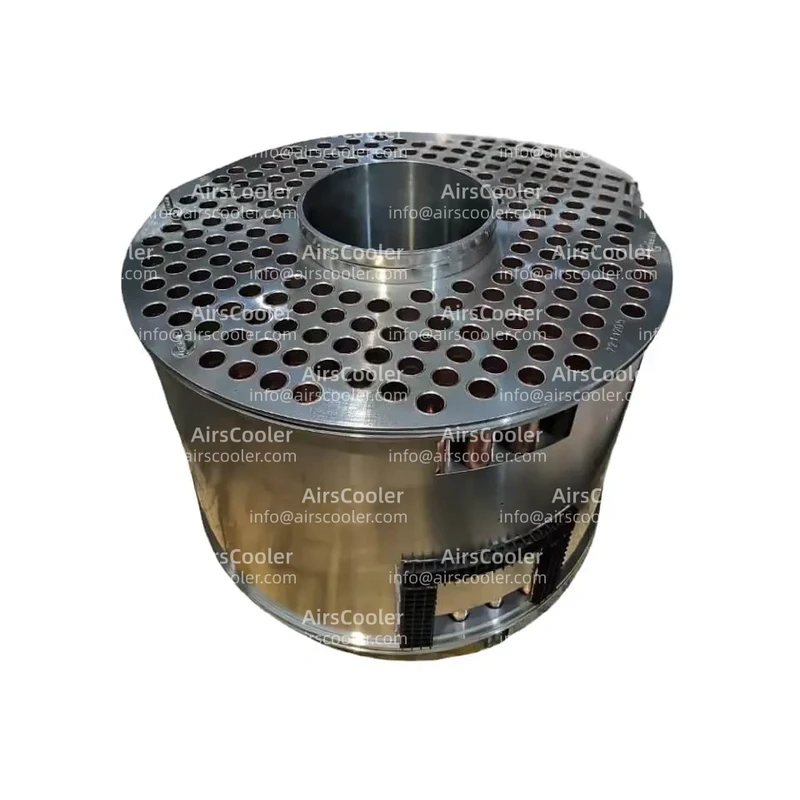

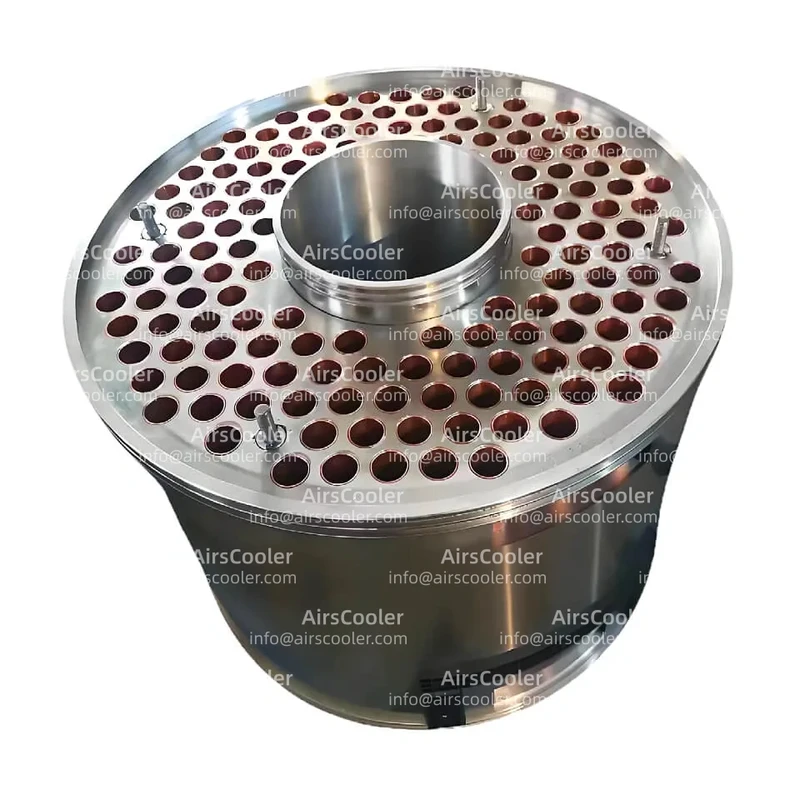

Centac Cooler 2ASB

Comprehensive technical breakdown and industrial applications of Fete Vessel's advanced air cooling solution for centrifugal compressors

1. Product Overview: Core module of Industrial Air Cooling system setups

The Centac Cooler 2ASB is a specialized heat exchange device built for Centac series centrifugal air compressors, classified as an air-cooled thermal exchanger. Its primary function is efficient heat removal through forced convection between air and compressed air, ensuring safe temperatures before downstream processes. Featuring modular design, it integrates with the compressor's chassis to form a compact power system setup with intercoolers and aftercoolers.

1.1 Technical and Market Positioning

As a critical module for industrial compressed air system setups, the 2ASB cooler meets high-pressure, high-flow thermal demands. Operating within 0.7-22.5kg/cm² pressure range and 720-51,000m³/h flow capacity, it serves precision temperature control use cases including petrochemical cracking, blast furnace system setups, and pharmaceutical clean air systems. Compared to water-cooled alternatives, it eliminates scaling issues and minimizes water treatment costs.

1.2 Structural Features

The 2ASB employs patented tube-in-shell design with air flowing through internally finned tubes (some models support pure air-cooling). Technical documentation shows 30-40% greater heat transfer area than conventional designs with 15-20% lower pressure loss. Rigid flange connections integrate cooling with compressor lubrication and control system setups for remote DCS monitoring.

2. Technical Specifications and Data Analysis

2.1 Core Heat Exchange Technology

- 3D Fin Enhancement: 2.5mm trapezoidal fins with 1.8mm spacing achieve 120-150W/(m²·K) convection coefficient

- Triple-Seal system setup: Graphite floating ring seals keep ≤0.01% leakage rate with TÜV oil-free certification

- Smart Cleaning: High-pressure rotary cleaning completes in ≤15 minutes (80% faster than acid washing)

2.2 operational performance Parameters

| Parameter | Specification | Test Condition |

|---|---|---|

| Max Heat Load | 3,200kW (water-cooled) | 120°C inlet, 35°C surrounding |

| Air pressure loss | ≤8kPa | ISO 1217 Standard |

| Cooling overall efficiency | ≥92% (water) / ≥85% (air) | NTU-ε Method |

| Pressure Rating | 25kg/cm² | ASME VIII Div.1 |

| Corrosion Resistance | C5-M | 316L Stainless + Epoxy Coating |

2.3 Innovation Highlights

Microchannel condensate formation: 0.8mm tubes minimize condensate film to 0.1mm, boosting heat transfer by 40% for high-pressure use cases. Phase Change Storage: Optional PCM modules cut energy costs 12-15% via off-peak storage. Digital Twin Monitoring: 200+ embedded sensors with AI predict maintenance needs, tripling service intervals.

3. use cases and Case Studies

3.1 Industry use cases

Petrochemical: Cools 180°C air to 40°C for ethylene crackers, improving yield by 0.3%. Semiconductor: provide -40°C dew point air meeting SEMI F27 standards. LNG Terminals: Handles 12,000Nm³/h boil-off gas with ≤3°C approach, reducing energy 18%.

3.2 Implementation Cases

PTA Chemical Plant: Three C700 compressors with 2ASB coolers achieved 6.2 COP (25% above industry) while saving 360,000t water annually. EV Battery Factory: Custom C1000 system setup keep ±0.5°C for electrode coating, reducing defects from 0.8% to 0.15% with UL 508A certification.

4. Maintenance Protocol

4.1 Preventive Maintenance

Daily: Check ≤15°C surface gradient and vibration ≤2.8mm/s. Monthly: Clean fins with 0.3MPa air and test 5-second flush response. Annual: Eddy current tube inspection and seal replacement at 15-20% compression.

4.2 Troubleshooting

Error Codes: E102 (over-temperature), E205 (tube leak >50ppm water), E311 (fan overload). Contingencies: Mobile cooling units keep ≥50% capacity during repairs with ≤4 hour MTTR.

4.3 Smart Maintenance

AR-guided diagnostics achieve 95% fault accuracy. Blockchain records help ensure full lifecycle traceability while digital twins enable 80% predictive maintenance coverage.

5. Conclusion

The Centac Cooler 2ASB demonstrates 25% energy savings, 100% water reduction, and 40% lower maintenance costs across petrochemical, semiconductor and energy use cases. With emerging phase-change and digital twin integration, AirsCooler's technology is poised to support hydrogen compression and carbon capture in achieving decarbonization goals.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 2C

View Details

View DetailsCentac Cooler 2CII

View Details

View DetailsCentac Cooler 2CV

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.