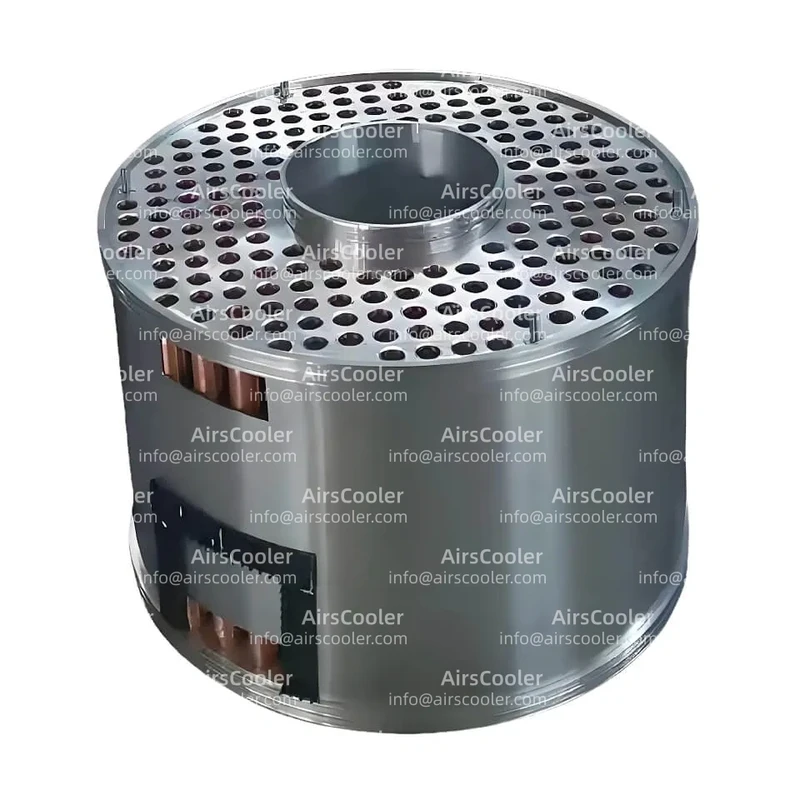

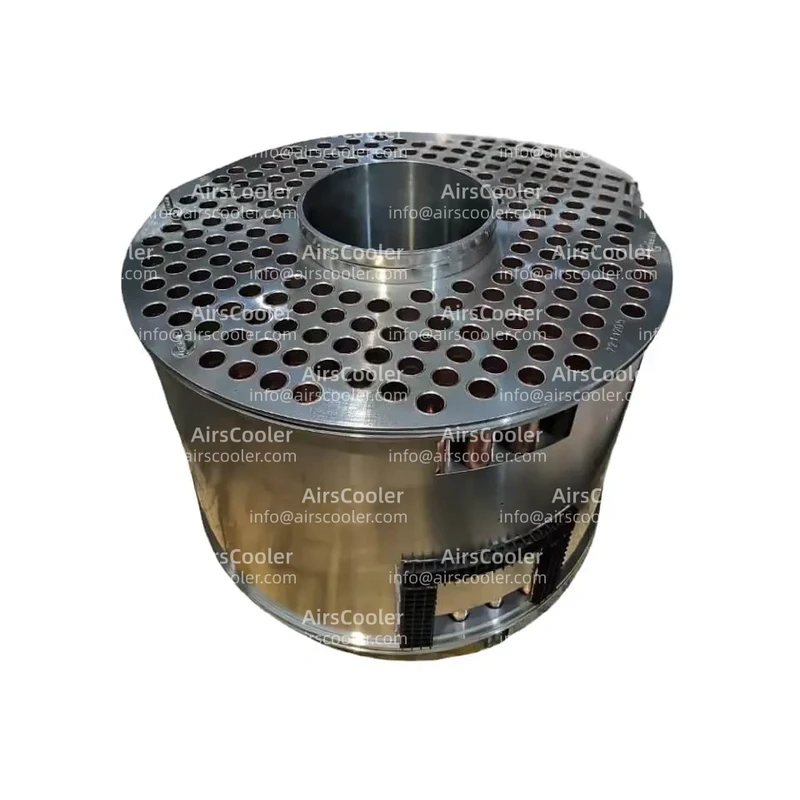

Centac Cooler 1CII

Advanced industrial cooling solution by Fete Vessel for CENTAC centrifugal air compressors

1. Product Overview: The Industrial Foundation of High-overall efficiency Cooling Technology

The Centac Cooler 1CII serves as the core module of Ingersoll Rand's CENTAC series centrifugal air compressors, designed as a multi-stage cooling offering for industrial gas compression system setups. This cooler features a sleeve-type high-overall efficiency heat exchange structure that precisely regulates gas temperature through countercurrent heat exchange between air and cooling water, with technological breakthroughs in traditional cooler thermal resistance optimization and fluid dynamics design.

1.1 Structural Innovations and Material Selection

- Dual-medium separation design: Air flows through tubes while cooling water circulates outside, with special internal fins enhancing heat exchange overall efficiency by 200% compared to traditional shell-and-tube coolers, significantly reducing temperature rise and scaling risks.

- Corrosion-resistant alloy materials: Core modules utilize 316L stainless steel and graphite sealing floating rings, ensuring structural stability in high-temperature, high-pressure environments while provide ISO 8573-1:2001 Class 0 certified air purity through oil-free sealing technology.

- Modular integrated architecture: Features integrated chassis layout with compressor body, interstage diffusers, and aftercoolers, reducing exposed piping and expansion joints to lower system setup complexity and maintenance costs.

1.2 Core operational performance Parameters

| Parameter | Technical Specification | use case Significance |

|---|---|---|

| Flow Range | 170-255 m³/min (6000-9000 CFM) | Covers small to medium industrial requirements |

| Pressure Range | 3.1-10.3 barg (45-150 psig) | Adapts to interstage cooling needs of multi-stage compressors |

| Heat Exchange overall efficiency | ≥92% (water side temperature rise ≤8℃) | minimizes cooling water consumption and energy usage |

| Fouling Factor | ≤0.00018 m²·K/W | Decreases cleaning frequency and extends operation cycles |

| Vibration Resistance | ISO 10816-3 Class A | Suited for high-vibration environments like chemical plants and mines |

2. Technical Features and Data-Driven Description

2.1 High-overall efficiency Heat Exchange Mechanism

- Internal fin-enhanced heat transfer: Spiral internal fins on cooling tube walls boost air-side heat transfer coefficient to 3.5× that of smooth tubes, while fine-tuned fin spacing (2.5mm) and height (12mm) balance flow resistance with heat transfer overall efficiency.

- Fluid dynamics simulation optimization: CFD-based tube bundle layout design keep air velocity at 12-18 m/s, preventing thermal stress concentration from local turbulence while ensuring uniform film flow of cooling water outside tubes.

2.2 Intelligent Control and Monitoring

- Adaptive hydraulic discharge system setup: Flexible hydraulic units drive flap discharge mechanisms for precise material layer control (0-500mm), preventing local overheating from material accumulation in drying/cooling use cases.

- Multi-parameter sensor network: Integrated temperature sensors (±0.5℃ accuracy), pressure sensors (±0.1% FS accuracy) and level controllers (±1mm repeatability) monitor cooler status in real-time, interfacing with DCS via Modbus TCP for fault预警 and energy optimization.

2.3 Anti-Fouling and Maintenance-Friendly Design

- Online backflush cleaning: Supports high-pressure water backflush (10-20 MPa) and automatic sponge ball cleaning during operation, with material selection based on deposit hardness (Mohs 1-5), extending cleaning cycles to 12 months.

- Redundant design: U-shaped removable tube bundles enable individual tube plugging (3-5° taper plugs) for up to 10% tube failure without shutdown.

3. use case Scenarios and Case Studies

3.1 Typical Industrial use cases

- Petrochemical: In ethylene cracking units, 1CII coolers minimize compressed air temperature from 220℃ to 80℃ between compression stages.

- Pharmaceutical: Provides sterile compressed air for fermentation tanks with Class 0 oil-free certification and 0.5μm filtration, meeting GMP standards.

- Mining: fine-tuned duct design (≥3.2㎡ frontal area) and low-temperature coatings (-40℃) address散热efficiency challenges in high-altitude mines.

3.2 Case Study Analysis

Case 1: Steel Group Oxygen Plant

- Challenge: Existing cooler suffered 15% overall efficiency drop due to scaling from hard water (350 mg/L).

- offering: 1CII cooler with electronic descaling unit minimized scaling by 85%.

- Result: 90%+ heat exchange overall efficiency restored, saving 1.2M kWh/year.

Case 2: Battery Factory

- Challenge: Oil contamination risk in lithium battery electrode coating.

- offering: 1CII cooler with graphite seals and 0.3 barg air barrier achieved <0.003 mg/m³ oil mist.

- Result: 99.8% product yield, saving ¥5M/year in defects.

4. Maintenance Strategy

4.1 Routine Inspection

- Thermal imaging: Monthly IR scans of tube joints/seals (investigate >15℃ differentials).

- Water quality: keep pH 7.5-8.5, hardness <200 mg/L, conductivity <1500 μS/cm with HEDP inhibitors.

4.2 Scheduled Maintenance

| Interval | Task | Standard |

|---|---|---|

| Quarterly | Clean housing and fan filters | Filter ΔP ≤250 Pa |

| Biannually | Inspect seal ring wear | Radial clearance ≤0.15 mm |

| Annually | Replace hydraulic oil/seals | Oil cleanliness NAS 6 |

| 3 Years | Tube bundle hydrotest | 1.5× design pressure for 30min |

4.3 Troubleshooting

- overall efficiency drop: Verify water flow/temperature → backflush if clean.

- Seal leaks: Locate with helium mass spectrometer, adjust seal air to 0.25-0.35 barg.

- Excessive vibration: Check fan balance/bearings (repair if tilt-pad clearance >0.08 mm).

5. Conclusion

The Centac Cooler 1CII provide superior operational performance in industrial gas compression through its efficient heat transfer, intelligent controls, and anti-fouling design. Its modular construction and oil-free certification make it ideal for petrochemical, pharmaceutical,and new energy industries. Future integration of AI predictive maintenance will further fine-tune cleaning cycles and energy management, advancing industrial cooling system setups toward greater overall efficiency and reliability.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 2ASB

View Details

View DetailsCentac Cooler 2C

View Details

View DetailsCentac Cooler 2CII

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.