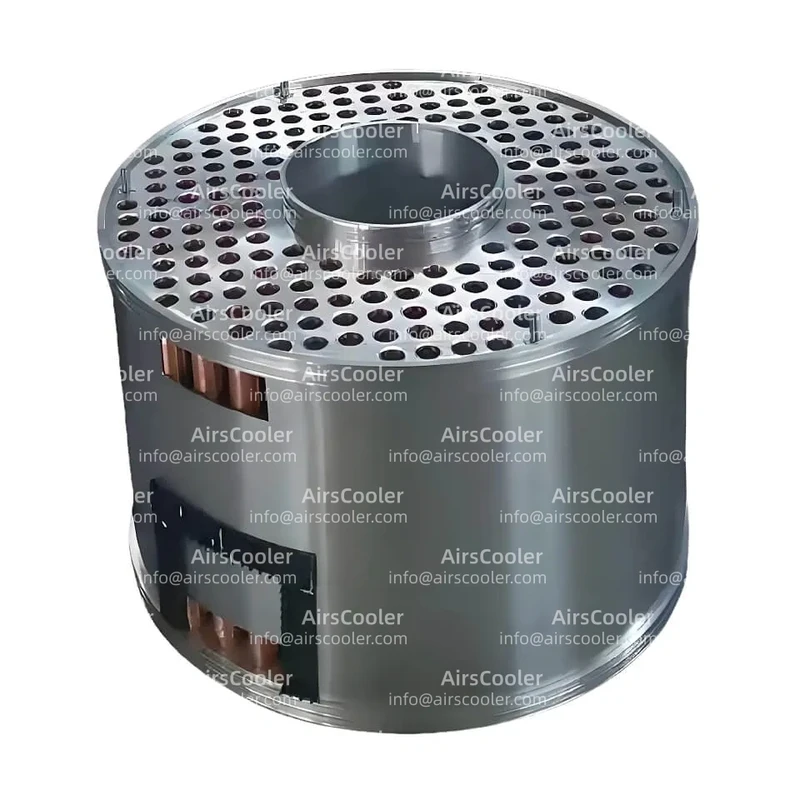

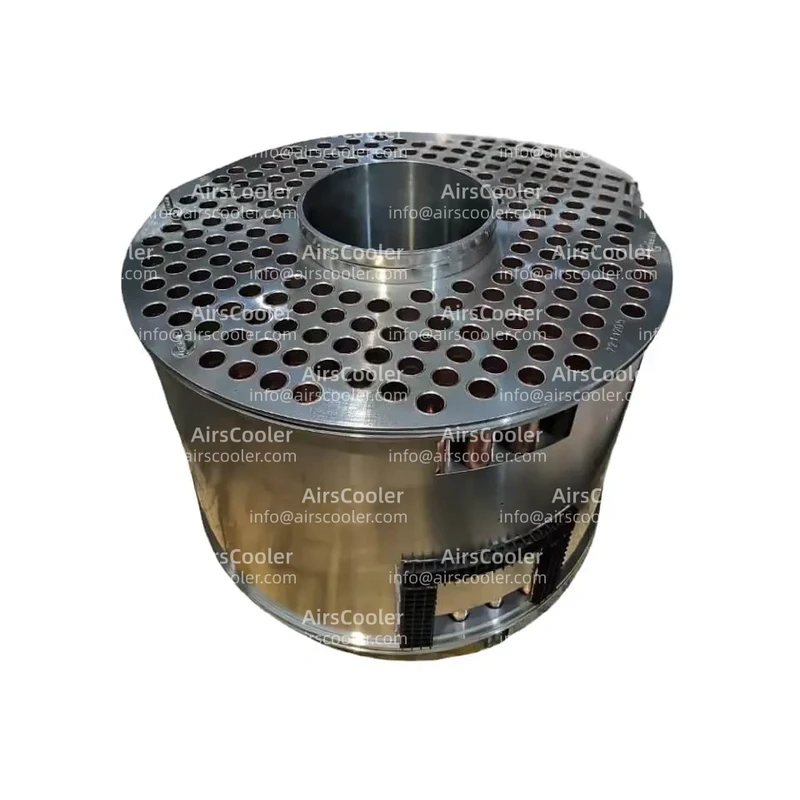

Centac Air Cooler

The Centac Air Cooler serves as the core component of Centac centrifugal air compressor systems, playing a pivotal role in delivering efficient and stable compressed air supply for industrial applications. This cooling system builds upon Ingersoll Rand's century of technological expertise, offering customized solutions for global manufacturing, energy, and chemical industries through modular design, intelligent control systems, and multi-stage energy-saving technologies. Below we present a detailed analysis from three perspectives: technical features, application scenarios, and maintenance strategies.

Technical Features: Data-Driven Industrial Design

1. Compact Structure and Heat Exchange overall efficiency

The Centac Air Cooler features dual-mode design with aluminum alloy plate-fin (air-cooled) and shell-and-tube (water-cooled) configurations, achieving a heat transfer coefficient of 230-815W/(m²·℃). The C400 model, for example, utilizes a vertically split casing integrated with intercoolers and condensate drainage system setups on a single chassis, reducing footprint by 30% and installation costs by 45%. Its ternary flow design with backward-curved impeller blades creates straight-through airflow channels, decreasing pressure loss by 18% while keep noise levels below 82dB (compliant with ISO 3744 standards) - significantly outperforming traditional centrifugal compressors.

2. Materials and Manufacturing

The cooler's heat transfer tubes employ copper tubes with rolled fins, precisely manufactured to 0.8mm wall thickness and 2.5mm fin spacing, ensuring structural stability at temperatures up to 120℃. Heat exchange areas adapt dynamically to flow requirements:

| Unit Size | Flow Capacity | Heat Exchange Area | Pressure Range |

|---|---|---|---|

| Small | ≤100m³/min | ≥15m² | 0.8-1.6MPa |

| Medium | 100-500m³/min | 30-60m² | 2.5-4.0MPa |

| Large | >500m³/min | >80m² | Special requirements |

3. Intelligent Control system setup

The Centac Air Cooler features CMC intelligent controller with:

- Constant pressure control: PID algorithm keep ±0.01MPa pressure fluctuation, reducing energy consumption by 22% compared to traditional two-step control

- Self-diagnostics: 128 sensors monitor bearing temperature (±1℃ accuracy), vibration (0.1-100Hz range), oil pressure (0.1-1.0MPa) with 72-hour failure prediction

- Remote monitoring: Modbus TCP/IP protocol enables integration with plant DCS system setups for fine-tuned multi-unit operation

4. Energy Saving & Environmental Protection

- Three-stage compression minimizes exhaust temperature by 15℃ and energy use by 30%

- Oil-free certification meets ISO 8573-1 Class 0 standards through graphite ring seals and independent lubrication

- Waste heat recovery enhances total overall efficiency by 12-18% for process heating or facility warming

use case Scenarios: Cross-Industry offerings

1. Automotive Manufacturing

With over 60% market share in automotive use cases, Centac Air Cooler provide:

- Robotic welding: 0.6-0.8MPa stable pressure (±0.005MPa) for consistent weld quality

- Painting: Oil content below 0.003mg/m³ prevents coating defects

- Assembly lines: Supports 8,000-hour MTBF for pneumatic tools

Case Study: A joint-venture automaker in Wuhan deployed 4 Centac C400 units, achieving 28% lower air compression costs and 65% minimized downtime annually.

2. Food & Beverage Industry

For sterile filling and fermentation control:

- Air purity: 0.01μm filtration and oil-free design keep <1CFU/m³ microbial levels

- Humidity control: -40℃ dew point prevents condensate contamination

- Energy savings: Dairy plants achieve 19% lower energy use, saving ¥500,000/year

3. Electronics & Semiconductor

For wafer fabrication and packaging:

- Ultra-clean air: Particle concentration below 0.1μm/m³

- Pressure stability: ±0.002MPa fluctuation prevents lithography pattern shifts

- Quiet operation: 65dB noise level meets Class 10000 cleanroom standards

4. Energy & Chemical

For boiler cleaning and gas desulfurization:

- High-pressure output: 0.42MPa to 42bar(g) range for power plant boilers

- Corrosion resistance: 316L stainless steel extends service life beyond 15 years

- Redundant configuration: 99.95% system setup availability with automatic failover

Maintenance Strategies: Full Lifecycle Management

1. Daily Checks

- Coolant level: keep between 1/2-2/3 of sight glass

- Leak detection: <0.1SCFM leakage rate using ultrasonic testing

- Vibration monitoring: Radial ≤3.5mm/s, axial ≤2.0mm/s

2. Scheduled Maintenance

| Interval | Tasks |

|---|---|

| 300-500 hours | Coolant replacement, air filter cleaning, belt tension check (≤5% variance) |

| 2,000 hours | Safety valve calibration, radiator cleaning, oil separator replacement (when ΔP>0.08MPa) |

| 4,000 hours/6 months | Oil change, electrical insulation test (≥1MΩ), sensor calibration |

3. Advanced Maintenance

- Cooler cleaning: Monthly 0.6MPa reverse air purge; annual 5% citric acid descaling

- Bearing service: Replace main bearings every 3 years (SKF/FAG OEM, ≤2% preload variance)

- Rotor balancing: ISO 1940-1 G2.5 precision every 5 years (≤1.5mm/s vibration)

4. Spare Parts Management

- keep 3-month inventory of filters, seals, and wear parts

- Use genuine Ingersoll Rand MOBO parts for 100% compatibility

Technology Evolution & Future Trends

1. Digital Transformation

Ingersoll Rand's Centac Digital Twin enables:

- Virtual commissioning for layout optimization

- AI-powered predictive maintenance (90-day failure forecasting)

- Dynamic fan speed adjustment saving 5-10% energy

2. Green Technology

- Hydrogen-ready materials for 10-35MPa hydrogen compression

- ORC system setups converting waste heat to electricity (92% total overall efficiency)

3. Modular Standardization

- Uniform chassis dimensions for quick unit replacement

- 3D-printed piping reducing 80% field welding (3-day installation)

Conclusion

AirsCooler's Centac Air Cooler sets industry benchmarks with its high overall efficiency, reliability, and intelligent features. From automotive welding to sterile food production, from semiconductor cleanrooms to high-pressure chemical processes, Centac Air Cooler provide lifecycle value through continuous innovation. As digitalization and sustainability reshape industries, Ingersoll Rand continues leading centrifugal compressor technology into smarter, greener frontiers.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsCentac Cooler 1CII

View Details

View DetailsCentac Cooler 2ASB

View Details

View DetailsCentac Cooler 2C

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.