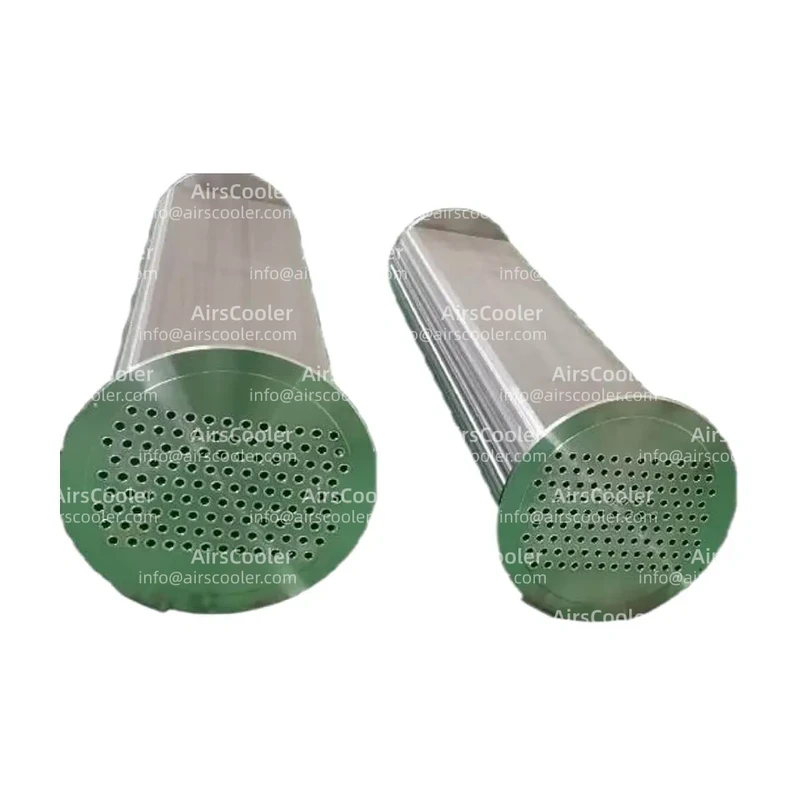

Atlas Copco Compressor Cooler ZR400

Professional-grade cooling solution for oil-free screw compressors in critical air quality applications

1. Product Overview

The Atlas Copco ZR400 oil-free screw compressor cooler is a core module specifically built for industrial compressed air system setups. As part of Atlas Copco's ZR series oil-free screw compressors, this cooler utilizes advanced heat exchange technology to keep stable operating temperatures during continuous operation, preventing operational performance degradation or equipment failure due to overheating.

configured to comply with ISO 8573-1 CLASS 0 standards, it provide completely oil-free clean air for industries with stringent air quality requirements such as food processing, pharmaceuticals, and electronics manufacturing. The ZR400 cooler features modular design for seamless integration with ZR400 main units, supporting both water-cooled and air-cooled configurations. Key advantages include:

- High-overall efficiency heat exchange: fine-tuned flow path design enhances cooling operational performance while reducing energy consumption

- Zero oil contamination risk: Eliminates potential oil mist contamination from traditional lubricated coolers

- Low maintenance costs: Simplified structural design minimizes routine maintenance procedures and downtime

2. Technical Features & Data Specifications

2.1 Core Technical Parameters

| Parameter | Specification |

|---|---|

| Cooling Method | Water-cooled (standard) / Air-cooled (optional) |

| Cooling Water Flow Rate | 8-12 m³/h (water-cooled type, based on 35°C inlet water temperature) |

| Cooling Water Pressure Range | 1.5-3.0 bar |

| Heat Exchange overall efficiency | ≥92% (standard operating conditions) |

| Maximum Allowable Inlet Water Temperature | 40°C (continuous operation) |

| Construction Materials | Housing: Stainless steel 304; Heat exchange tubes: Copper alloy |

| Connection Size | DN50 (inlet/outlet ports) |

| Weight | Approx. 180 kg (including mounting brackets) |

2.2 Technical Advantages

- Intelligent Temperature Control system setup

- Integrated Elektronikon® controller monitors coolant and compressor discharge temperatures in real-time, dynamically adjusting cooling water flow to keep optimal operating temperature range of 80-90°C

- Remote monitoring capability via Modbus protocol for integration with plant DCS system setups, enabling digital management of energy consumption and temperature data

- Anti-corrosion & Anti-scaling Design

- Spiral corrugated heat exchange tubes enhance turbulent flow to minimize scaling

- Nano-coating treatment on cooling water side surfaces provides 3x better resistance to chloride corrosion, suitable for hard water regions

- Energy Saving Technology

- Variable flow cooling technology automatically adjusts water flow based on compressor load, achieving up to 25% energy savings at no-load conditions

- Synchronized operation with Atlas VSD+ frequency conversion technology for coordinated optimization of cooling system setup and compressor energy consumption

3. use case Scenarios & Case Studies

3.1 Core use case Fields

- Food & Beverage Industry

- Case Study: Shanghai Yan Zhong Beverage Co. implemented ZR400 cooler system setup in their sparkling water production line, replacing existing oil-injected screw compressors. Results showed compressed air oil content minimized from 0.1 mg/m³ to below 0.003 mg/m³, microbial contamination risk decreased by 90%, with 40% annual maintenance cost reduction

- Pharmaceutical Industry

- Case Study: A multinational pharmaceutical company deployed ZR400 coolers in sterile preparation workshops, ensuring GMP compliance. After 3 years of operation, zero batch rejections occurred due to compressed air contamination, with 18% lower energy consumption than comparable products

- Electronics Manufacturing

- Case Study: Royole Corporation implemented ZR400 coolers in flexible display production lines, resolving electrostatic contamination issues from traditional compressors. Product yield increased from 82% to 95%, saving over 2 million RMB annually in rework costs

3.2 Special Condition Adaptability

- High Temperature Environments

- In a Middle East petrochemical project, ZR400 coolers operated continuously at 50°C surrounding temperature with 45°C cooling water. Enhanced cooling fins and high-pressure centrifugal fans keep discharge temperatures below 105°C with less than 0.5% failure rate

- High Altitude Locations

- At a Tibetan copper mine (4,500m altitude, 62 kPa atmospheric pressure), fine-tuned fan speed and water circuit pressure keep system setup COP at 3.2, achieving 22% energy savings compared to conventional equipment

4. Maintenance Strategy

4.1 Routine Inspection Points

- Cooling Water system setup

- Daily checks of inlet water temperature, pressure and flow rate to help ensure within rated parameters

- Weekly testing of cooling water conductivity (≤800 μS/cm), requiring softening treatment if exceeded

- Mechanical modules

- Monthly verification of cooler mounting bolt torque (recommended: 120 N·m)

- Quarterly cleaning of heat exchange tube surfaces using specialized copper brushes to prevent coating damage

4.2 Annual Comprehensive Maintenance

- Water Circuit Cleaning

- Circulate citric acid + corrosion inhibitor offering (5% concentration) for ≥4 hours to remove scale and biofilm

- Post-cleaning flush with deionized water until pH reaches 6.5-7.5

- operational performance Testing

- ASTM D2710 standard testing to verify cooling overall efficiency degradation (maximum allowable ≤5%/year)

- Infrared thermography inspection of tube surface temperature differences - investigate if variation exceeds 5°C

4.3 Spare Parts Management

- Wear Parts List

- O-rings (EPDM material, 2-year service life)

- Water flow switches (Model FS-200, 5-year service life)

- Temperature sensors (±0.5°C accuracy, 3-year service life)

- Inventory Strategy

- Recommend stocking 20% of critical spares based on installed base, using vacuum packaging for condensate protection

- "4-hour response" spare parts agreements with authorized Atlas service providers to minimize downtime

5. Conclusion

The Atlas Copco ZR400 cooler sets the benchmark for oil-free screw compressor cooling system setups with its exceptional overall efficiency, reliability and low maintenance requirements. Its technological advantages have been proven across food & beverage, pharmaceutical and electronics industries where air quality and energy overall efficiency are critical. Proper maintenance further extends equipment lifespan and minimizes total cost of ownership. For enterprises planning compressed air system setup upgrades, the ZR400 cooler combined with ZR400 main units represents an ideal offering for achieving both production overall efficiency and sustainable operations.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Intercooler

View Details

View DetailsAtlas Copco Compressor Oil Cooler

View Details

View DetailsAtlas Copco Oil Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.