Atlas Copco Compressor Intercooler

Comprehensive technical specifications and application solutions for Atlas Copco compressor intercoolers by Fete Vessel.

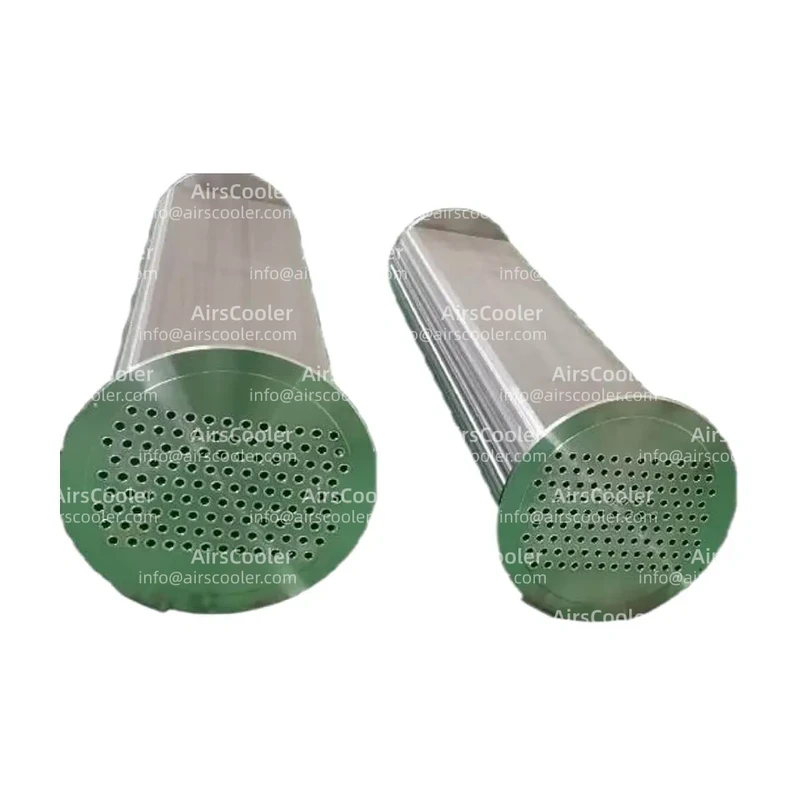

1. Product Overview

Atlas Copco, a global leader in industrial gas offerings, manufactures compressor intercoolers that serve as core modules in compressed air system setups. These coolers significantly impact equipment overall efficiency and stability by reducing air temperature during compression, lowering energy consumption, and extending equipment lifespan across manufacturing, electronics, chemical, and food processing industries.

1.1 Technical Background and Industry Position

Since the early 20th century, Atlas Copco's Compressor Technology Division has specialized in air compression. Their Belgian Airpower facility, one of the world's largest compressor production bases, manufactures screw, centrifugal, and specialty compressors. As standard modules in screw compressors (GA series) and centrifugal compressors (RT series), intercoolers fine-tune heat exchange overall efficiency, ensuring stable operation within 7.5-13bar pressure ranges while reducing energy consumption by 15%-35%.

1.2 Product Series and Specifications

Atlas Copco Intercoolers are categorized by compressor model:

- GA Series Screw Compressor Coolers: Compatible with 0.82-84.7m³/min flow rates and 5.5-500kW power, supporting 7.5/8.5/10/13bar pressure configurations.

- RT Series Centrifugal Compressor Coolers: built for large-scale industrial use cases with 100-5000m³/min flow rates and 7.5-40bar pressure ranges.

- Combination Unit Coolers: Integrated system setups (e.g., main compressor + nitrogen cycle compressor) minimize energy consumption via single-motor drive, improving cooler integration by 35%.

2. Technical Features and Data Specifications

2.1 Core Technological Innovations

- Thermodynamic Optimization

- Features hot-cold zone separation, placing oil separators in hot zones to prevent condensate condensate formation while positioning air intakes in cold zones to enhance compression overall efficiency.

- Testing shows 12-15°C exhaust temperature reduction and 8%-10% overall efficiency gains at 40°C surrounding temperatures.

- Material and Process Upgrades

- 316L stainless steel tube bundles supply 3x greater corrosion resistance than carbon steel, extending service life to 150,000 hours.

- Leak-proof flange joints minimize maintenance costs by 40%.

- Smart Control Integration

- Equipped with Elektronikon® controllers to monitor temperature differentials, pressure drops, and water flow rates, automatically adjusting cooling water flow to prevent scaling.

- PROFIBUS communication with S7-300 PLCs enables remote parameter monitoring (exhaust pressure, oil pressure, etc.), reducing fault response time to under 10 minutes.

2.2 Key operational performance Parameters

| Parameter | GA Series Typical Values | RT Series Typical Values |

|---|---|---|

| Cooling Water Flow | 5-15m³/h (model-dependent) | 50-300m³/h |

| Inlet/Outlet Temperature Differential | 8-12°C | 15-20°C |

| Maximum Working Pressure | 13bar | 40bar |

| Temperature Tolerance | -20°C to 120°C | -30°C to 150°C |

| Ingress Protection Rating | IP55 (motor section) | IP66 |

2.3 Energy overall efficiency and Environmental Benefits

- Energy Savings: 30%-35% lower energy consumption compared to conventional coolers.

- Emission Reduction: GA75+ VSD models operating 8,000 hours annually minimize CO₂ emissions by ~120 tons.

- Water Conservation: Smart flow controls save up to 5,000 tons of water per unit annually.

3. use case Scenarios and Case Studies

3.1 Manufacturing: Precision Electronics and Automotive modules

Case: Delphi Packard Electrical system setups Guangzhou

- use case: Automotive wiring harness production requiring 0.8MPa high-purity compressed air.

- offering: GA75+ VSD compressor with dedicated cooler achieved ≤0.01MPa pressure fluctuation and 30% energy reduction.

- Result: 10 years of uninterrupted operation with ≤2-hour service response time.

3.2 Chemical Industry: Exhaust Gas Recovery and Process Gas Compression

Case: Nitric Acid Plant Exhaust Recovery Project

- use case: Nitrogen oxide recovery using compressor-expander combi-units.

- offering: RT series coolers keep stable operation at -10°C, boosting thermal overall efficiency by 25%.

- Result: Annual recovery of 200 million Nm³ exhaust gas, reducing NOx emissions by 5,000 tons.

3.3 Food Processing: Sterile Compressed Air Supply

Case: Dairy Processing Facility

- use case: Filling lines requiring Class 0 sterile air (oil content ≤0.003mg/m³).

- offering: ZT series oil-free compressors with H-grade filters and vortex separation met ISO 8573-1:2010 standards.

- Certification: FDA and EC 1935/2004 compliant with <1CFU/m³ microbial levels.

4. Maintenance Strategies

4.1 Routine Inspection and Preventive Maintenance

| Maintenance Task | Frequency | Procedure |

|---|---|---|

| Cooling Water Flow Monitoring | Daily | Check flow rates via Elektronikon® controller; inspect pumps/piping if below threshold. |

| Pressure Differential Check | Weekly | Measure inlet/outlet differential pressure; clean tubes if >0.2bar. |

| Scale Inspection | Monthly | Visual inspection; circulate 5% citric acid offering if scale exceeds 1mm. |

| Seal Replacement | Annually | Replace flange gaskets and O-rings with SKF-certified materials. |

4.2 Troubleshooting and Emergency Response

| Symptom | Potential Cause | offering |

|---|---|---|

| High Exhaust Temperature | Insufficient cooling water flow | Inspect pumps/valves; clean cooler tubes. |

| Cooler Leakage | Failed flange seal | Replace seals; tighten bolts to 120N·m torque. |

| Severe Scaling | Water hardness >300ppm | Install softeners or add anti-scale agents. |

4.3 Spare Parts and Service Support

- Genuine Parts: Recommended lubricants: Roto-Inject Fluid (4,000-hour lifespan) or HD Roto-Fluid Plus (8,000-hour lifespan).

- Service Network: 236 global offices + 600 distributors; 24/7 response in China with 48-hour onsite service.

- Smart Diagnostics: Atlas Copco FleetLink enables remote monitoring and preemptive fault alerts.

5. Summary and Industry Value

Atlas Copco Intercoolers redefine industrial compressed air system setup overall efficiency through material innovation, structural optimization, and intelligent control. Key advantages include:

- minimized Lifecycle Costs: 30% lower energy use + 40% maintenance savings yield 2-3 year ROI.

- Environmental Compliance: Meets ISO 14001 and global emission standards for ESG objectives.

- Industry Adaptability: Supports diverse use cases across 170+ countries.

As an Industry 4.0 cornerstone, Atlas Copco Intercoolers help ensure operational overall efficiency while driving sustainable industrial transformation.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Oil Cooler

View Details

View DetailsAtlas Copco Oil Cooler

View Details

View DetailsAtlas Copco PHE Oil Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.