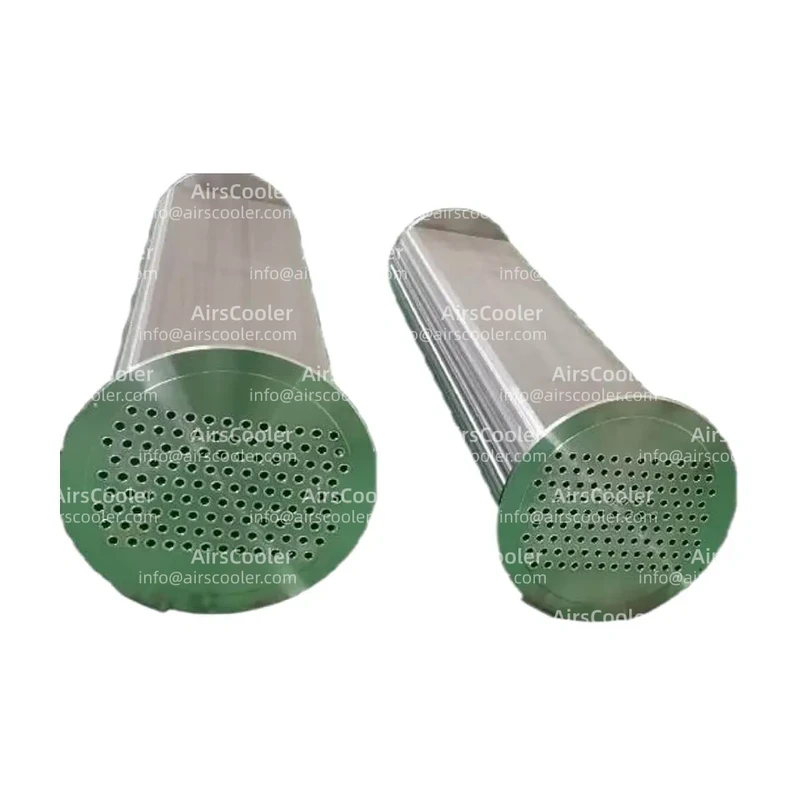

Atlas Copco Oil Cooler

Professional-grade cooling solutions for industrial compressor systems by Fete Vessel

1. Product Overview

The Atlas Copco Oil Cooler serves as the core module in compressor system setups, maintaining stable lubricant temperature, extending equipment lifespan, and enhancing energy overall efficiency. This product line includes two main types: water-cooled (HD series) and air-cooled (TD series), widely used in industrial manufacturing, construction, mining, and energy sectors.

Key Design Advantages

- keep oil temperature within 50-80℃ range to prevent oil degradation

- minimizes bearing wear and system setup corrosion

- Patented vertical design in GA VSD+ series saves 30% floor space

- ±2℃ temperature stability during continuous operation

2. Technical Specifications

Structural Innovations

- Vertical Oil Cooling Drive Chain: 2-3x longer bearing life with full oil lubrication

- H-grade Insulation: Withstands 180℃ with samarium-cobalt magnets (250-350℃ demagnetization temp)

- CFD-fine-tuned Oil Channels: 40% minimized flow resistance

Cooling overall efficiency Data

| Parameter | Water-cooled HD Series | Air-cooled TD Series | Test Conditions |

|---|---|---|---|

| Cooling Capacity | 50-300kW | 30-200kW | 40℃ surrounding |

| pressure loss | ≤0.01bar | ≤0.015bar | 100% flow rate |

| Noise Level | ≤68dB(A) | ≤72dB(A) | 1m distance |

| IP Rating | IP66 | IP55 | - |

3. use case Case Studies

Automotive Paint Shop

After installing GA VSD+ compressors with oil coolers:

- 92% reduction in downtime

- Annual electricity savings: 280,000 kWh ($21,000)

- Oil temperature stability enhanced from ±10℃ to ±1.5℃

Coal Mine Crusher Station

TD Series air-cooled oil cooler operational performance:

- IP66 rating extended filter replacement to 3 months

- system setup availability increased from 78% to 99%

- $1.2M annual savings from minimized downtime

4. Maintenance Guide

Routine Checks

- Oil Quality: Quarterly TAN testing (≤1.0mgKOH/g)

- Cooling operational performance: Weekly cleaning of cooling fins

- Leak Detection: Monthly checks with ≤5ppm sensitivity

Troubleshooting Guide

| Symptom | Possible Cause | offering |

|---|---|---|

| High Oil Temp | Insufficient coolant flow | Verify pump pressure ≥0.3MPa |

| Temperature Fluctuation | Stuck thermal valve | Clean/replace thermal valve |

5. Conclusion

Atlas Copco Oil Coolers set industry standards with three core advantages:

- Patented vertical design

- High-overall efficiency cooling technology

- Smart control system setups

With industry-leading specifications (≤0.015bar pressure loss, IP66 rating, 8,000+ hour lifespan) and proven results across multiple industries, these oil coolers provide complete thermal management solutions that minimize lifecycle costs by 25-35% while maintaining over 90% OEE.

AirsCooler provides comprehensive support for all Atlas Copco Oil Cooler use cases, from selection to maintenance.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco PHE Oil Cooler

View Details

View DetailsAtlas Copco Compressor Cooler ZHC10000

View Details

View DetailsAtlas Copco Heat Exchanger

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.