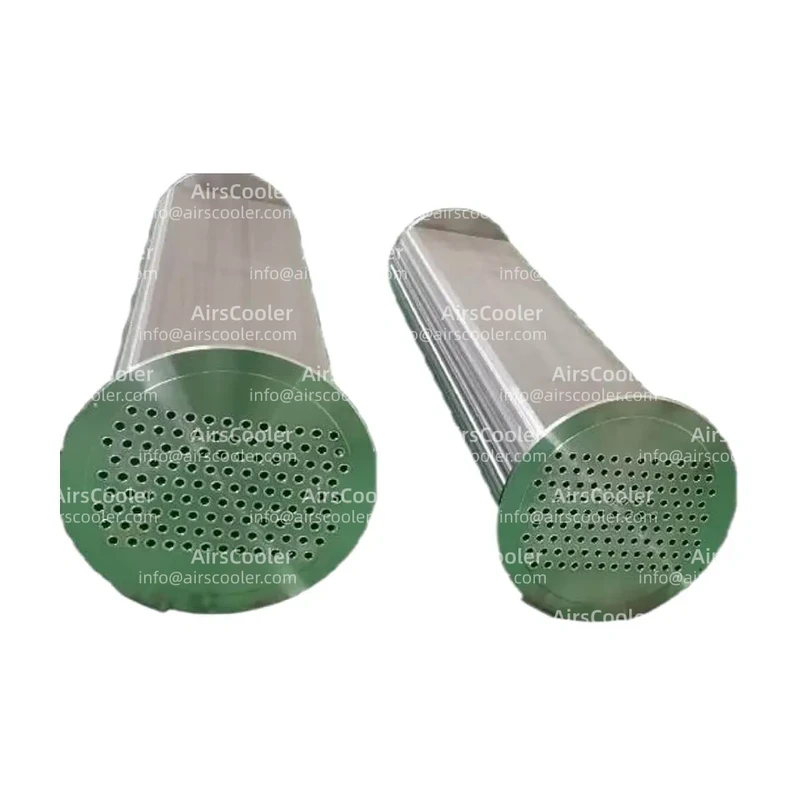

Atlas Copco Compressor Oil Cooler

Professional cooling solutions for industrial air power systems by Fete Vessel

1. Product Overview: Core Cooling Unit for Industrial Air Power system setups

Atlas Copco, as a global leader in industrial gas offerings, provides compressor oil coolers that serve as critical modules for screw-type, centrifugal, and oil-free compressor system setups. These coolers keep optimal oil temperatures (typically 60-85°C) through advanced heat exchange technology, preventing lubrication degradation, bearing wear, and excessive energy consumption.

2. Technical Features and Data Specifications

2.1 Structural Innovation and Material Science

The oil cooler features 316L stainless steel corrugated fin tubes with a surface area density of 1200m²/m³, provide 40% better heat exchange overall efficiency than conventional smooth tubes.

| Parameter | GA 75+ VSD Model Data | Industry Standard Comparison |

|---|---|---|

| Heat Exchange Power | 85kW (at 40°C surrounding temperature) | Standard coolers ≤60kW |

| Oil Temperature Control Accuracy | ±1°C (PID closed-loop control) | Standard ±3°C |

| pressure loss | Oil side ≤0.05MPa, Air side ≤150Pa | Industry standard ≤0.1MPa/300Pa |

3. use case Scenarios and Case Studies

3.1 High-Precision Manufacturing

Case: Delphi Packard Electric system setups Guangzhou Branch minimized oil temperature fluctuation from ±5°C to ±1°C, decreasing bearing wear rate by 40% and saving 180,000 kWh annually.

4. Maintenance Strategy

4.1 Daily Inspection Points

Monitor oil temperature daily and check for dust accumulation if temperature exceeds 85°C for three consecutive days.

5. Conclusion: Technological Innovation Drives Industrial overall efficiency

Atlas Copco compressor oil coolers redefine thermal management standards through material science, fluid dynamics, and intelligent control integration, helping industries achieve energy savings and carbon reduction goals.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Oil Cooler

View Details

View DetailsAtlas Copco PHE Oil Cooler

View Details

View DetailsAtlas Copco Compressor Cooler ZHC10000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.