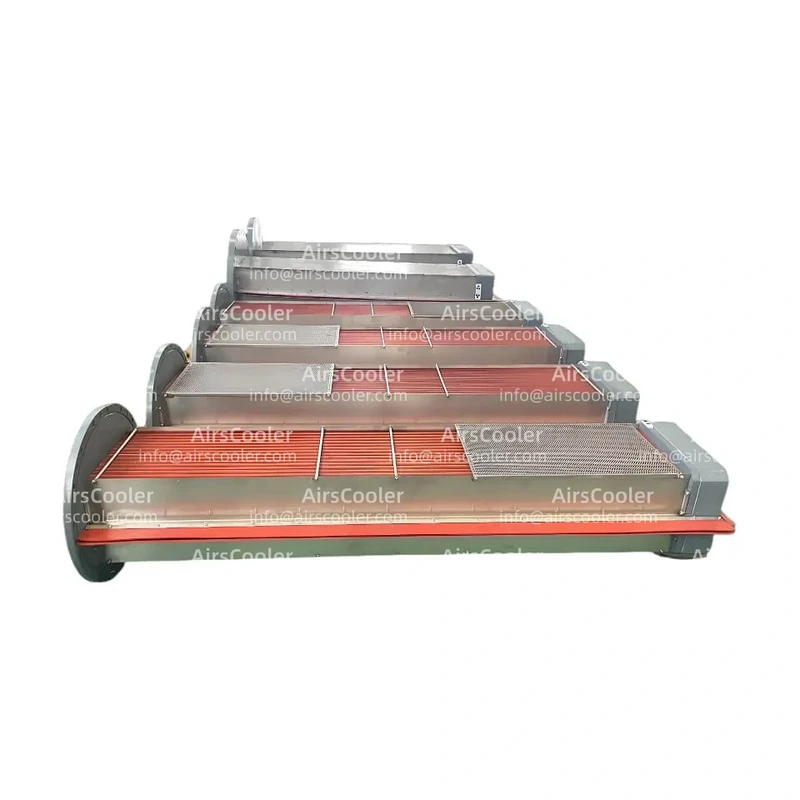

Atlas Copco Compressor Cooler ZR250

Professional-grade cooling solution for industrial air compression systems by Fete Vessel

1. Product Overview

Atlas Copco (Atlas Copco), as a global leader in air compressor manufacturing, supply the ZR250 series oil-free screw air compressor cooler as a core module in industrial compressed air system setups. The ZR250 cooler utilizes multi-stage compression and efficient heat exchange technology to rapidly dissipate heat generated during compression, ensuring stable operation in constant temperature environments. This cooler is configured to be compatible with multiple models in the ZR250 series, including standard models, variable speed models (VSD), and different pressure versions (such as 8.6bar and 10bar), meeting operational requirements for exhaust volumes of 40-50.46m³/min.

Core Functional Positioning

- Heat Load Capacity: built for the 250kW motor power of ZR250 models, the cooler achieves heat exchange for over 40m³ of compressed air per minute, controlling outlet air temperature within 15°C above surrounding temperature.

- Environmental Protection & Energy overall efficiency: Features dual water/air cooling modes with oil-free compression technology, eliminating lubrication oil leakage risks and meeting clean air standards for pharmaceutical and food industries.

- system setup Integration: Works with compressor main units, dryers, and filters to form a complete compressed air post-treatment system setup, ensuring end-use air quality compliance.

2. Technical Features & Data Specifications

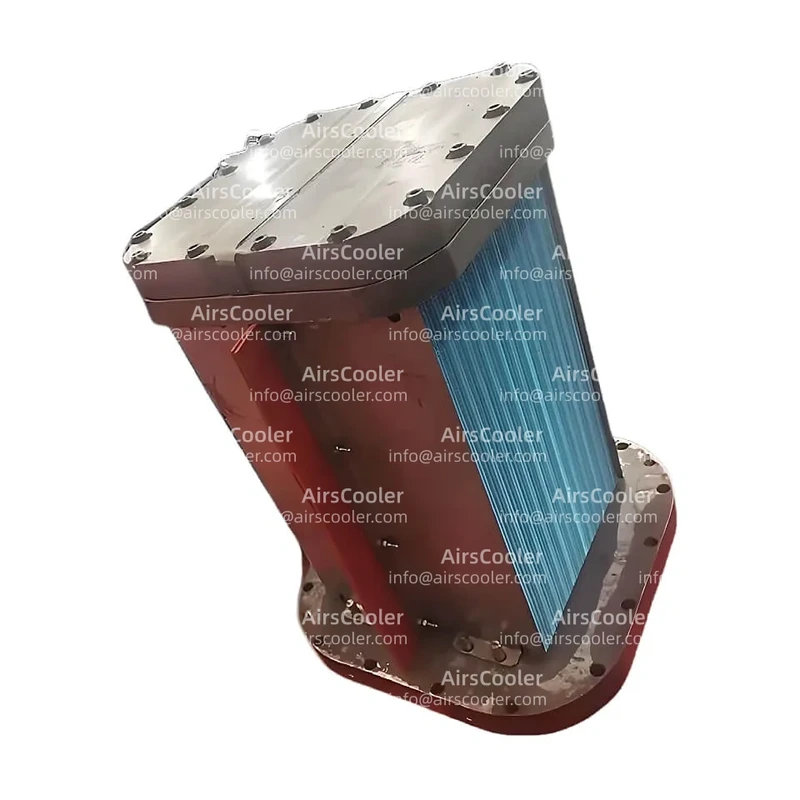

1. Structural Design Parameters

- Cooling Methods:

- Water-Cooled: For environments ≥35°C or high-altitude areas, requiring cooling water flow ≥15L/min with inlet water temperature ≤32°C.

- Air-Cooled: Uses axial fan forced convection with air volume ≥8000m³/h, noise ≤75dB(A), suitable for industrial environments with dust concentration ≤50mg/m³.

- Heat Exchange overall efficiency:

- High-overall efficiency copper tube fin thermal exchanger with heat transfer coefficient ≥200W/(m²·K), 30% more efficient than traditional aluminum heat exchangers.

- Water-cooled models minimize compressed air temperature from 120°C to ≤40°C with an 80°C temperature gradient.

- Materials & Manufacturing:

- Heat exchange tubes made of TP304 stainless steel with corrosion resistance meeting ASTM A249 standards, service life ≥10 years.

- 2.5mm fin spacing with hydrophilic aluminum foil coating enhances anti-scaling operational performance by 40%.

2. operational performance Data Indicators

| Parameter | Value Range | Test Conditions |

|---|---|---|

| Rated Exhaust Volume | 40-50.46m³/min (8.6-10bar) | ISO 1217 Standard Conditions (20°C, 1bar) |

| Cooling Water Flow (Water-Cooled) | 15-25L/min | Inlet Water 32°C, Outlet ≤40°C |

| Fan Power (Air-Cooled) | 3-5.5kW | surrounding Temperature 40°C |

| pressure loss | ≤0.03MPa | Full Load Operation |

| Protection Rating | IP55 | Compliant with IEC 60529 Standard |

3. Innovative Technology use cases

- Intelligent Temperature Control: Integrated DTC control panel monitors cooling water temperature, flow rate, and thermal exchanger surface temperature in real-time, automatically adjusting fan speed or water valve opening to minimize energy consumption by 15%.

- Modular Design: Flange connection between cooler and compressor main unit enables online replacement, reducing maintenance time to under 2 hours.

- Freeze Protection: Water-cooled models feature electric heating strips and temperature sensors that activate freeze protection when surrounding temperature ≤5°C, preventing heat exchange tube cracking.

3. use case Scenarios & Case Studies

1. Industry use cases

- Electronics Manufacturing: Provides ≤-40°C dew point air for wafer dicing and PCB printing processes, preventing electrostatic discharge risks.

- Pharmaceutical Industry: A vaccine manufacturer using ZR250VSD variable speed models keep compressed air oil content below 0.003mg/m³, meeting GMP certification requirements.

- Aerospace: Aircraft brake system setup testing requires 0.8MPa high-pressure air supply, with the cooler supporting ZR250-7 models for 72-hour continuous stable air supply with pressure fluctuation ≤±0.02MPa.

- Chemical Industry: During polyethylene reactor pressurization, the cooler withstands 150°C high-temperature gas impact while optimizing fin structure to minimize thermal stress below 120MPa.

2. Detailed Case Analysis

- Case 1: Semiconductor Packaging Plant

- Problem: Oil-injected screw compressors caused chip yield to drop to 85% due to oil content.

- offering: Upgraded to ZR250VSD with water-cooled cooler minimized oil content to 0.001mg/m³, increasing yield to 98% with annual cleaning cost savings of ¥2 million.

- Data: Cooler outlet temperature decreased from 95°C to 38°C with 22% energy reduction.

- Case 2: New Energy Vehicle Battery Plant

- Problem: Electrode coating required stable -60°C dew point air, but original equipment's 0.08MPa pressure loss caused uneven coating thickness.

- offering: ZR250 cooler + adsorption dryer combination fine-tuned pressure loss to 0.02MPa with ±2°C dew point stability, improving battery capacity consistency by 15%.

4. Maintenance Strategies

1. Routine Maintenance

- Cooling Water Quality Management:

- Hardness ≤150ppm, pH 6.5-8.5, tested monthly.

- Corrosion inhibitors (e.g., molybdate) keep at 50-100ppm concentration.

- Filter Replacement Cycles:

- Air Filters: Replace every 2000 hours or when pressure difference reaches 0.05MPa.

- Cooling Water Strainers: Clean every 500 hours, replace every 3000 hours.

2. Comprehensive Maintenance Plan

| Maintenance Level | Interval | Key Procedures | Material Cost |

|---|---|---|---|

| Level 1 | 8000 hours | Clean thermal exchanger scale, inspect fan bearing clearance | ¥8,000 |

| Level 2 | 16000 hours | Replace seals, measure heat exchange tube wall thickness | ¥15,000 |

| Overhaul | 40000 hours | Replace fin assemblies, test heat exchange overall efficiency | ¥35,000 |

3. Troubleshooting & Repair

- Common Issue 1: High Outlet Temperature

- Causes: Scale buildup, fan failure, insufficient cooling water flow.

- offerings:

- Chemical cleaning with EDTA tetrasodium (5% concentration, 60°C, 4-hour circulation).

- Replace faulty fans (recommended: EBM-PAPST model 4826N).

- Common Issue 2: Cooler Leakage

- Detection: Charge with nitrogen to 0.5MPa, keep pressure for 24 hours - acceptable if pressure loss ≤0.01MPa.

- Repair: Mechanical tube expansion + high-frequency brazing composite process, post-repair pressure test must withstand 1.5x working pressure.

5. Conclusion

The Atlas Copco ZR250 cooler provide an efficient, robust, low-maintenance industrial cooling solution through multi-stage compression heat management, modular design, and intelligent control system setups. Its dual water/air cooling modes adapt to various conditions while oil-free operation meets high cleanliness requirements in electronics, pharmaceuticals, aerospace and other advanced manufacturing sectors. With proper maintenance, the equipment achieves ≥15-year service life and 30% lower lifecycle costs than conventional models. As industries pursue carbon neutrality goals, the ZR250 cooler's energy overall efficiency makes it the premier choice for compressed air system setup upgrades.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor AfterCooler

View Details

View DetailsSamsung TM900 Intercooler

View Details

View DetailsSamsung Compressor Cooler SM2100

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.