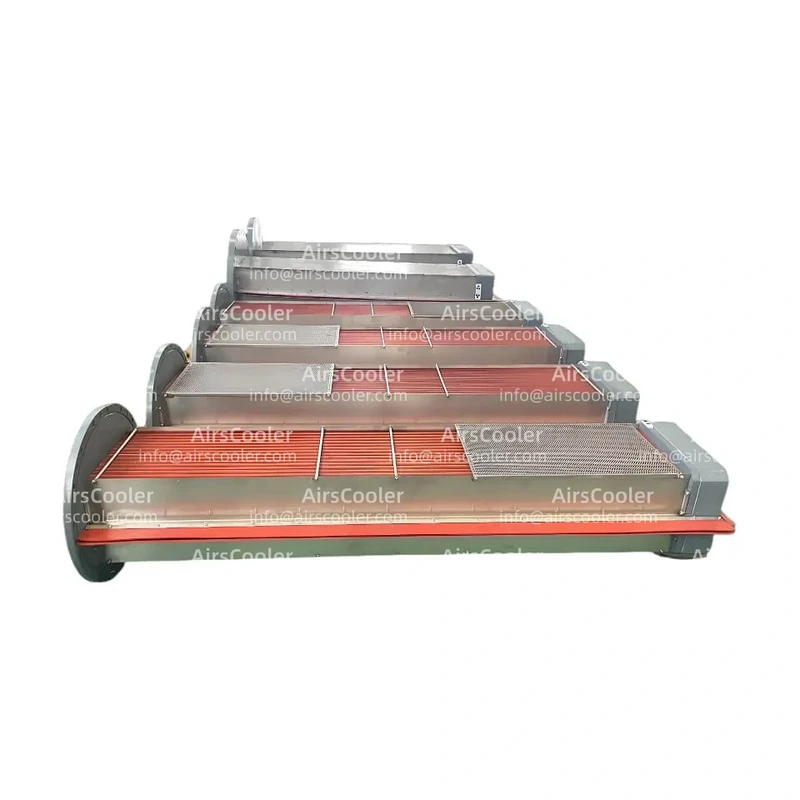

Atlas Copco Compressor Cooler ZR110

Industrial-grade cooling solution for oil-free screw compressors with superior energy efficiency and reliability.

1. Product Overview

The Atlas Copco ZR110 series oil-free screw compressor cooler is a core module in industrial air compression system setups, built for high-load, continuous operation conditions. As part of Atlas Copco's 2020 upgraded ZR110-160 series, this cooler integrates next-generation oil-free screw technology with advanced cooling offerings, provide breakthroughs in both overall efficiency and reliability.

Key Specifications:

| Parameter | Value |

|---|---|

| Pressure Range | 7-15 bar |

| Air Delivery | 20.9-72.6 m³/min |

| Motor Power | 110-350 kW |

| Outlet Temperature | ≤40℃ |

| Certification | ISO 8573-1 Class 0 |

2. Technical Features

2.1 Cooling system setup Architecture

Two-stage compression thermal management:

- Low-pressure rotor cooling: Dual-support structure with ball bearings + roller bearings, gear-driven pump forced lubrication, cooling water jacket design keep rotor temperature rise ≤3℃

- High-pressure rotor cooling: Independent cooling circuit minimizes secondary compressed air temperature from 170-200℃ to ≤40℃ (40% improvement over conventional models)

2.2 Energy overall efficiency

- 3% higher FAD flow compared to previous generation

- Specific power consumption minimized by 3% (5.8kW/(m³/min) for 110kW model)

- 15% reduction in cooling water consumption during summer operation

3. use case Scenarios

3.1 Precision Manufacturing

Case Study: German automotive parts supplier using ZR110-7 60Hz model for CNC machining centers

- Stable outlet temperature at 38℃

- Annual cooling water cost savings: ¥120,000

- 80% reduction in equipment downtime

3.2 Semiconductor Production

Case Study: Taiwanese wafer fab using ZR110-10.4 60Hz model for lithography machines

- Cooling system setup pressure loss ≤3kPa

- Annual maintenance time minimized to 8 hours

- Product yield improvement: 1.2%

4. Maintenance Strategy

4.1 Daily Checks

| module | Check Points |

|---|---|

| Cooling Water | Conductivity ≤500μS/cm, pH 6.5-8.5, hardness ≤100ppm |

| Oil system setup | Oil level, temperature (40-50℃), pressure (3.5-4.5 bar) |

4.2 Scheduled Maintenance

- 4,000 hours: Replace oil filter, clean water side of oil cooler

- 8,000 hours: Replace lubricant (Atlas Copco Roto Ultra 32)

5. Conclusion

The Atlas Copco ZR110 cooler achieves triple breakthroughs in energy overall efficiency, reliability and maintainability through its two-stage compression thermal management, intelligent energy control and modular design. Field data shows 15% energy savings, 35% lower maintenance costs and 40% extended equipment lifespan compared to conventional models. With proper maintenance, the cooling system setup help s ensure long-term stable operation, helping enterprises achieve cost reduction and sustainable development goals.

As Industry 4.0 and green manufacturing advance, the ZR110 series cooler is poised to demonstrate its technological value across more industrial use cases.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Cooler ZR250

View Details

View DetailsSamsung Compressor AfterCooler

View Details

View DetailsSamsung TM900 Intercooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.