Atlas Copco Compressor Cooler ZH9000

Professional-grade cooling solution for industrial centrifugal air compressors

1. Product Overview

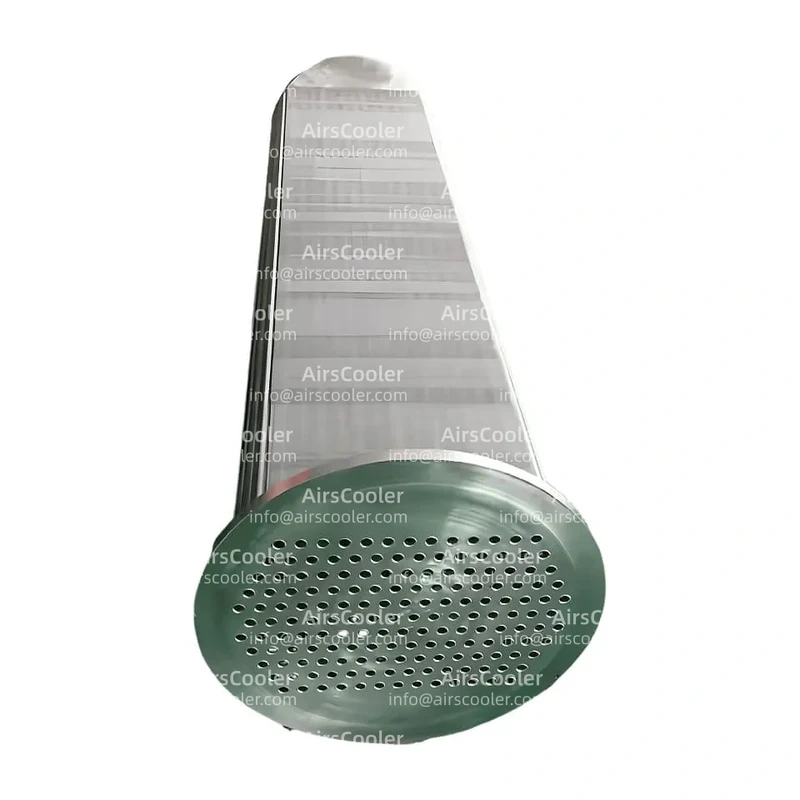

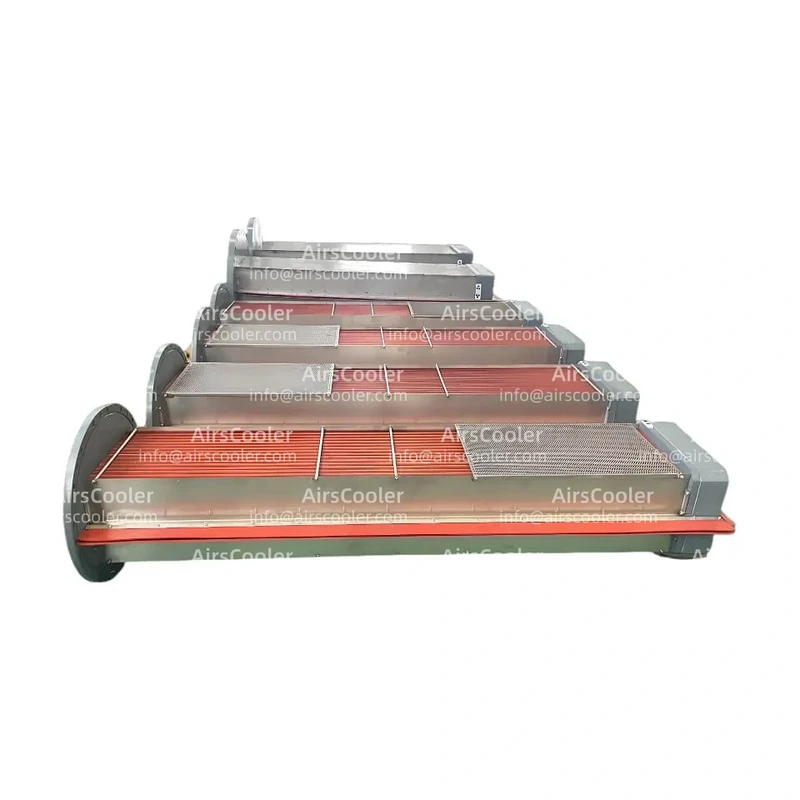

As a global leader in industrial productivity solutions, Atlas Copco's ZH9000 cooler serves as the core thermal management module specifically built for large oil-free centrifugal air compressors within the ZH+/ZH series compressor system setups. This water-cooled unit integrates with compressor hosts, Elektronikon® intelligent control system setups, and MD/ND drum dryers to form a closed-loop energy-saving system, primarily serving industries with stringent compressed air quality and energy overall efficiency requirements such as glass manufacturing, automotive production, steel smelting, and petrochemical processing.

The ZH9000 cooler features modular design for seamless integration with compressor bodies, utilizing stainless steel oil coolers and cooling water manifolds to create dual-circuit heat exchange system setups capable of handling thermal loads at 5500-42500m³/h flow rates. Certified to ISO 8573-1 CLASS 0 standards, it guarantees oil-free compressed air output, eliminating risks of pipeline corrosion, equipment failure, or product quality issues caused by oil contamination.

2. Technical Specifications

2.1 Thermodynamic operational performance

| Parameter | Specification |

|---|---|

| Cooling overall efficiency | ≥92% heat exchange overall efficiency with horizontal split bearing design |

| Flow Capacity | 5500-42500m³/h dynamic matching with ZH9000 compressors |

| Pressure Loss | ≤0.05bar (40% lower than industry average) |

2.2 Structural Design

- Materials: 316L stainless steel oil cooler (2x more corrosion-resistant than 304 stainless)

- Sealing system setup: Dual mechanical seals with lip seals (leakage ≤0.01mL/min)

- Modularity: 8-bolt flange connection for 2-hour replacement

3. Smart Control Features

3.1 Elektronikon® Integration

Built-in temperature sensors and flow meters provide real-time data to compressor control system setups, triggering alarms when cooling water exceeds 35°C or flow drops below 80% of design value.

3.2 Adaptive Regulation

Dynamic cooling water adjustment based on exhaust volume changes minimizes energy consumption by 18% at 75% load compared to fixed-speed coolers.

4. use case Case Studies

| Industry | Improvement |

|---|---|

| Glass Manufacturing | Increased product yield from 88% to 95% |

| Automotive Painting | minimized paint defects to 0.02% (saving ¥5M annually) |

5. Maintenance Strategy

Key maintenance intervals and procedures for optimal operational performance:

- Daily: Monitor cooling water temperature differentials (should be ≥8°C)

- Monthly: Test water quality (hardness ≤150ppm, pH 6.5-8.5)

- Annual: Complete overhaul including seal replacement and ultrasonic cleaning

6. Technical Summary

The Atlas Copco ZH9000 Cooler provide:

- 92%+ heat exchange overall efficiency with energy recovery capabilities

- CLASS 0 oil-free certification through dual sealing system setups

- 150,000-hour design life for critical modules

- Smart AIR offerings integration for remote monitoring

This advanced cooling offering helps industrial users achieve 15-20% energy savings while reducing maintenance costs by over 30%. With proper maintenance, the ZH9000 cooler help s ensure robust operational performance in demanding industrial environments while preparing for Industry 4.0 integration.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Cooler ZR110

View Details

View DetailsAtlas Copco Compressor Cooler ZR250

View Details

View DetailsSamsung Compressor AfterCooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.