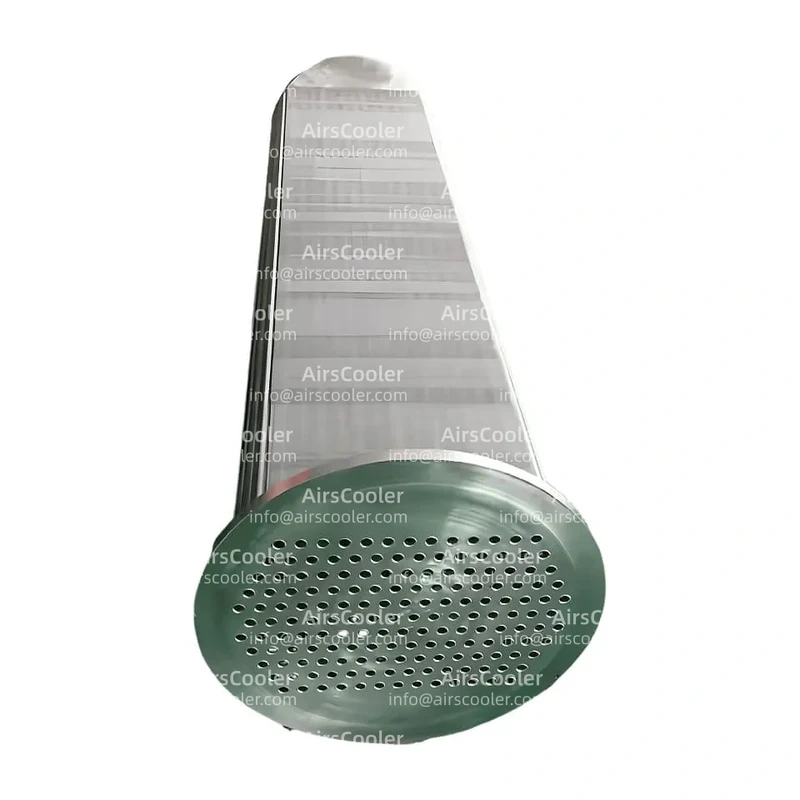

Atlas Copco Compressor Cooler ZH7000

Comprehensive technical specifications and practical application solutions for the ZH7000 cooling system in industrial environments.

1. Product Overview

The Atlas Copco ZH7000 cooler is a core module specifically built for centrifugal air compressors, representing the high-end cooling module in the ZH series. This product features all-stainless steel TIG welding technology with a compact structure and high heat exchange overall efficiency, achieving minimal liquid retention through thin plate design. Its primary function is to provide efficient heat exchange for centrifugal compressors, ensuring stable output of compressed air under high-pressure and high-temperature conditions while reducing energy consumption and operational noise. This cooler is widely used in industrial manufacturing, energy, chemical, and environmental protection sectors, particularly excelling in scenarios requiring continuous and stable air supply.

2. Technical Features and Data Specifications

2.1 Core Parameters and operational performance Indicators

- Operating Conditions: Compatible with ZH7000 centrifugal compressors, rated working pressure range of 7-10.4bar (50Hz), supporting 6 flow configurations with maximum exhaust capacity up to 20m³/min (varies by specific model).

- Cooling overall efficiency: Requires only 1/3 of the water consumption compared to traditional shell-and-tube thermal exchangers, reducing cooling water flow demand by 67%.

- Pressure Capacity: Withstands up to 16bar design pressure, operating temperature range from -20°C to 150°C.

- Materials: 316L stainless steel body with 0.5-0.8mm plate thickness, 100% radiographic testing of welds, leakage rate below 1×10⁻⁹ Pa·m³/s.

- Hydraulic Design: Fouling factor ≤0.00015m²·℃/W, minimizes fouling deposition rate by 70% at flow velocities of 3-5m/s.

2.2 Innovative Technologies

- Modular Design: Supports quick disassembly and capacity expansion up to 3-stage series configuration.

- Smart Temperature Control: Integrated sensors and flow valves keep ±1°C accuracy.

- Noise Reduction: Operational noise ≤75dB(A), 10-15dB lower than comparable products.

- Energy overall efficiency: Specific power ≤5.5kW/(m³/min), saving 12%-18% energy versus traditional coolers.

2.3 operational performance Comparison Data

| Parameter | ZH7000 Cooler | Traditional Shell-and-Tube Cooler | Improvement |

|---|---|---|---|

| Cooling Water Requirement | 10m³/h | 30m³/h | -67% |

| Fouling Factor | 0.00015 | 0.00045 | -67% |

| Maintenance Interval | 24 months | 12 months | +100% |

| COP | 4.2 | 3.5 | +20% |

| Weight | 850kg | 1200kg | -29% |

3. use case Scenarios and Case Studies

3.1 Primary use case Fields

- Manufacturing: Automotive painting lines, clean rooms for electronic modules

- Energy Sector: Natural gas stations, oilfield booster stations

- Environmental Engineering: Wastewater aeration system setups, flue gas denitrification

- Food Processing: Aseptic packaging lines, beverage filling equipment

3.2 Detailed Case Studies

Case 1: Overhaul Project at Fujian Chemical Plant

- Replaced bearings with SAE 52100 steel (HRC60-62 hardness)

- Upgraded to 3-stage ZH7000 cooler configuration

- Results: Vibration minimized from 15μm to 2.3μm, annual electricity savings of ¥800,000

Case 2: Automotive Paint Shop Upgrade

- Implemented ZH7000 system setup with ±0.05bar pressure stability

- Achieved ISO 8573-1 Class 0 air quality

- Results: Paint quality enhanced from 85% to 98.5%, OEE increased by 22%

4. Maintenance Strategy

4.1 Routine Inspection Points

- Coolant pressure differential ≤0.15MPa

- Compressed air outlet temperature ≤40°C

- Helium leak detection ≤1×10⁻⁹ Pa·m³/s

- Vibration analysis ≤4.5mm/s

4.2 Scheduled Maintenance

- 500-hour Service: Surface cleaning, pH verification (6.5-8.5)

- 8000-hour Service: Ultrasonic cleaning, O-ring replacement

- 24000-hour Service: Full plate replacement, pressure testing at 1.5x design pressure

4.3 Troubleshooting

- Insufficient Coolant Flow: Check pump head (≥25m), clean 80-mesh filters

- Oil Contamination: Verify separator differential pressure (≤0.1MPa)

- Surge Events: Activate backup within 30 seconds, minimize load to 70%

5. Conclusion

The Atlas Copco ZH7000 cooler sets industry benchmarks in overall efficiency, reliability and smart functionality for industrial compressed air system setups. Field use cases demonstrate 15%-20% operational cost reductions while improving production quality. As Industry 4.0 advances, the ZH7000 series will incorporate enhanced digital features for complete lifecycle management, provide competitive compressed air offerings from AirsCooler.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Cooler ZH9000

View Details

View DetailsAtlas Copco Compressor Cooler ZR110

View Details

View DetailsAtlas Copco Compressor Cooler ZR250

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.