Atlas Copco Compressor Cooler ZH15000

Comprehensive technical specifications, performance data, and maintenance strategies for Fete Vessel's premium industrial cooling solution

1. Product Overview

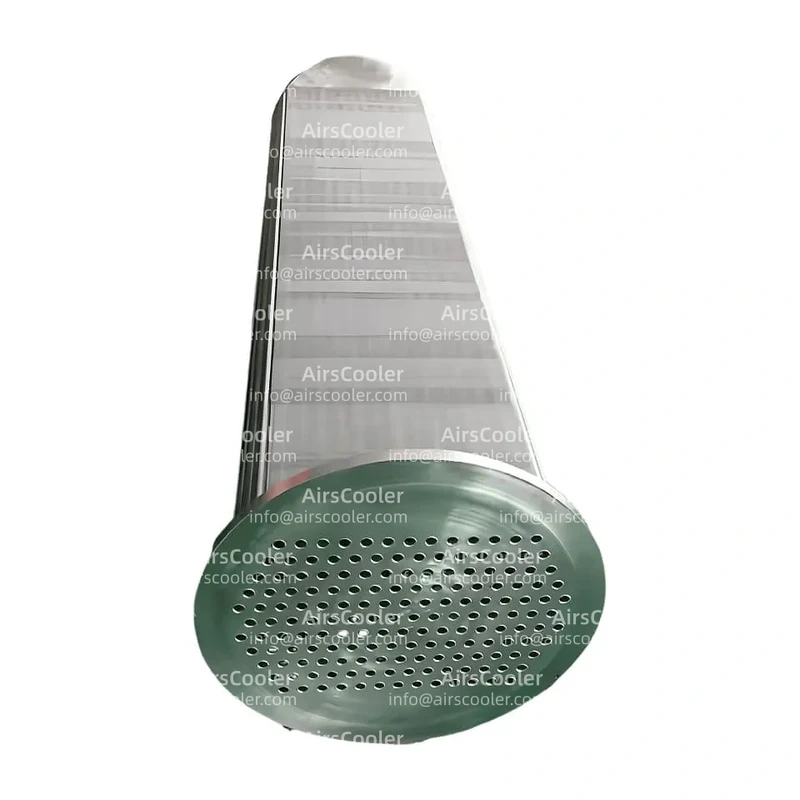

The Atlas Copco Compressor Cooler ZH15000 is a specialized cooling unit designed by Atlas Copco for large industrial centrifugal air compressor system setups, belonging to the ZH series centrifugal air compressor matching modules. This product adopts modular water-cooled structure, specifically providing high-overall efficiency heat exchange offerings for air compression processes under high-load working conditions. Its core function is to transfer heat generated during compression from the compressed medium through circulating cooling water system setup, ensuring stable operation of the air compressor and extending the service life of key modules.

Technical Background and Market Positioning

The ZH15000 cooler leverages Atlas Copco's technical expertise in centrifugal compressors, with fine-tuned design for heavy industrial use cases such as chemical, steel, and petrochemical industries. Its technical specifications strictly match the exhaust volume (5500-42500m³/h) and working pressure (1-13bar) of ZH series centrifugal machines (like ZH15000 main unit), ensuring overall system setup energy overall efficiency. Domestic suppliers including Wuxi Chaoke Refrigeration Equipment Co., Ltd. and Wuxi Blue Star Pressure Vessel Co., Ltd. produce through technical authorization, with products certified by ISO 9001 quality management system setup and compliant with industrial equipment reliability requirements.

2. Technical Features and Data Description

1. Structure and Heat Exchange Principle

- Double-pass baffle enhanced heat transfer: The cooler adopts shell-and-tube structure with cooling water flowing inside tubes while compressed air forms double-pass or four-pass flow between tubes through intermediate baffles, significantly improving heat exchange overall efficiency. Under typical parameters, its heat exchange area reaches 1200mm×930mm (Wuxi Blue Star product specifications), with heat transfer coefficient 15%-20% higher than conventional designs.

- Pressure and flow adaptability: Design pressure range covers 0.8-1.6MPa, supporting cooling requirements for compressed air with flow range 200-500m³/min. Water-side pressure loss ≤0.05MPa, air-side pressure loss ≤0.02MPa, ensuring system setup energy overall efficiency.

- Material and corrosion resistance: Main body material uses 304 stainless steel or nickel-plated carbon steel, tube bundle adopts high-frequency welded finned tubes, with temperature resistance range -20℃ to 150℃, suitable for circulating water environment with chloride ion concentration ≤50ppm, meeting requirements for coastal or chemical plant conditions.

2. operational performance Parameters and Energy overall efficiency Indicators

| Parameter Category | Technical Indicators | Typical use case Scenarios |

|---|---|---|

| Cooling overall efficiency | ≥95% (ΔT=15℃) | Blast furnace air system setup in steel smelting |

| Water-side Flow Rate | 80-150m³/h | Air separation unit in petrochemical industry |

| Air-side Inlet Temperature | ≤120℃ (peak transient 150℃) | Compressed air system setup for glass melting furnace |

| Water-side Inlet Temperature | 25-35℃ | Sterile workshop in food & beverage industry |

| Cooling Water Quality Requirements | Conductivity ≤1500μS/cm, hardness ≤1.5mmol/L | Automobile painting workshop |

3. Intelligent Design and Compatibility

- Remote monitoring interface: Pre-configured Modbus RTU protocol interface, compatible with Atlas Elektronikon® control system setup, real-time monitoring of cooler inlet/outlet water temperature, pressure and flow, supporting fault warning and energy overall efficiency analysis.

- Modular expansion capability: Seamless integration with ZH series centrifugal machine's three-stage compression system setup, single cooler can adapt to 1-3 compression units, meeting phased capacity expansion needs.

- Redundancy design: Dual-circuit water path structure, keep over 70% cooling capacity during single tube bundle leakage, ensuring production continuity.

3. use case Scenarios and Case Studies

1. Core use case Fields

- Chemical process gas compression: In ethylene cracking units, ZH15000 cooler minimizes cracked gas temperature from 120℃ to 40℃, preventing carbide deposition in subsequent compression process and reducing equipment maintenance frequency.

- Blast furnace air supply in steel smelting: A steel plant case shows after adopting this cooler, air compressor exhaust temperature decreased, motor load minimized, achieving annual electricity savings of 500,000kWh.

- Food-grade compressed air preparation: A dairy company configured ZH15000 cooler to minimize compressed air oil content below 0.01ppm, meeting sterile filling workshop requirements with significant improvement in product microbial indicators.

2. Typical Case Analysis

Case 1: Air separation unit renovation in petrochemical plant

- Problem: Original cooler caused air compressor exhaust temperature exceedance due to scaling blockage, triggering interlock shutdown.

- offering: Replaced with ZH15000 cooler featuring double-pass baffle design, fine-tuned water-side flow velocity, minimized cooling water circulation volume and system setup energy consumption.

- Result: Stable air compressor exhaust temperature after renovation, minimized annual maintenance cost and spare parts consumption.

Case 2: New energy vehicle battery production line

- Requirement: Compressed air must meet CLASS 0 oil-free standard with temperature fluctuation controlled within ±2℃.

- Configuration: ZH15000 cooler + stainless steel material + online cleaning device.

- Outcome: Stable compressed air dew point temperature, enhanced battery electrode coating yield, increased annual production capacity.

4. Maintenance Strategy

1. Routine Inspection and Preventive Maintenance

- Key parameter monitoring: Daily recording of cooling water inlet/outlet temperature, pressure difference and flow rate, establishing trend analysis model. When water-side pressure difference exceeds initial value, tube bundle endoscopy inspection required.

- Water quality management: Monthly testing of circulating water conductivity, pH value and hardness to help ensure compliance. If hardness exceeds standard, softening treatment or scale inhibitor addition needed.

- Mechanical integrity check: Quarterly inspection of tube bundle vibration, ensuring support plate spacing meets design requirements, avoiding tube bundle fracture caused by resonance.

2. Fault Diagnosis and Emergency Handling

| Fault Phenomenon | Possible Causes | offerings |

|---|---|---|

| Cooling overall efficiency decline | Tube bundle scaling, baffle blockage | Chemical cleaning (citric acid + corrosion inhibitor) or high-pressure water jet cleaning |

| Leakage | Tube bundle corrosion, sealing gasket aging | Replace damaged tube bundle or seals, local repair welding |

| Excessive water-side pressure loss | Tube bundle foreign matter blockage, uneven water distribution | Backflush operation or install online filtration device |

3. Shutdown Maintenance and Overhaul

- Annual overhaul content:

- Disassemble and inspect tube bundle corrosion condition, ultrasonic thickness measurement for wall thinning;

- Replace all sealing gaskets and bolt fasteners;

- Reapply anti-corrosion coating;

- Calibrate safety valves and pressure gauges.

- Spare parts management: Recommend stocking key spare parts including tube bundles, sealing gaskets, pressure sensors, with inventory cycle not exceeding 2 years.

5. Conclusion

The Atlas Copco Compressor Cooler ZH15000 has become a core module of compressed air system setups in heavy industries due to its efficient heat exchange operational performance, rigorous industrial-grade design and intelligent management capabilities. Through digital parameter management, typical scenario verification and preventive maintenance strategies, this product can significantly enhance user production overall efficiency and minimize lifecycle costs. With the advancement of Industry 4.0 and dual-carbon goals, the ZH15000 cooler will further integrate intelligent predictive maintenance functions, providing more sustainable offerings for energy-intensive industries.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Cooler ZH7000

View Details

View DetailsAtlas Copco Compressor Cooler ZH9000

View Details

View DetailsAtlas Copco Compressor Cooler ZR110

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.