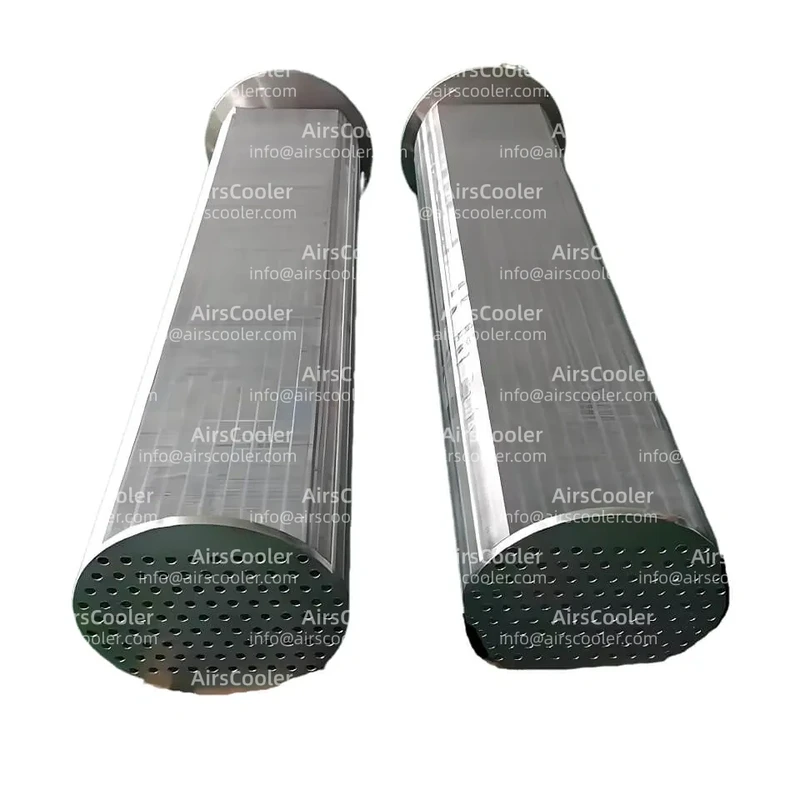

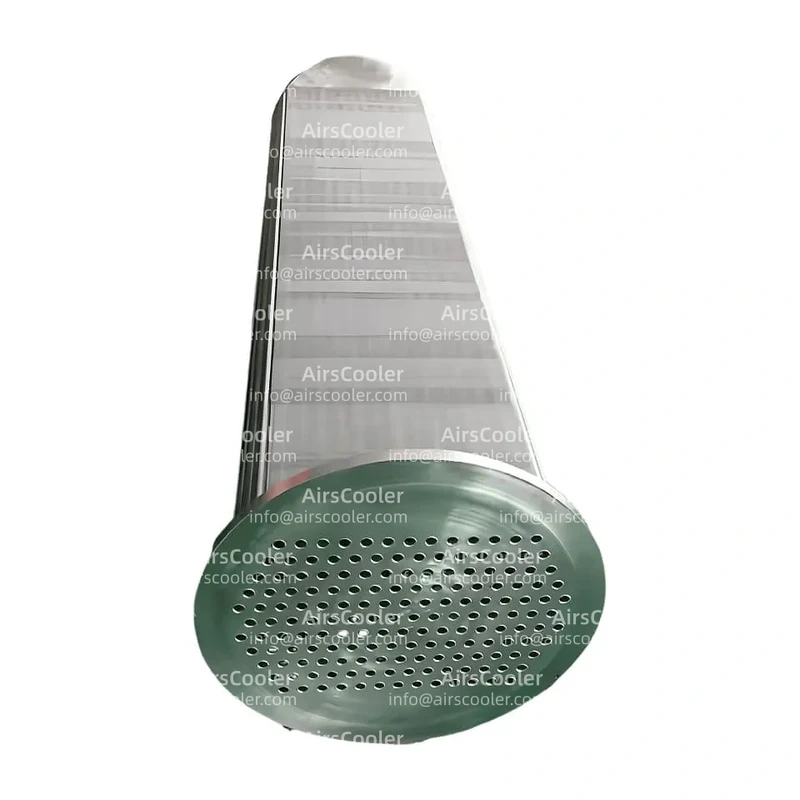

Atlas Copco Compressor Cooler ZH10000

Comprehensive technical specifications and practical applications of Fete Vessel's premium industrial cooling solution

1. Product Overview

The Atlas Copco ZH10000 centrifugal compressor cooler is a core module specifically built for industrial-grade air compression system setups, belonging to the Atlas Copco ZH series centrifugal machine cooling module. This cooler achieves efficient heat exchange through a three-stage compression structure, utilizing a water-cooled circulation system setup that adapts to the ZH10000 model compressor's 7-10.4bar (e) working pressure range, covering operational requirements of 100-150psi (60Hz).

2. Technical Features and Data Description

Core operational performance Parameters

Heat Exchange overall efficiency

Features plate-type heat exchange structure with 300% higher heat transfer coefficient compared to traditional shell-and-tube designs, reducing liquid holdup to 1/3 of industry standards and decreasing cooling water flow requirements by 67% under equivalent conditions.

Materials and Manufacturing

Main heat exchange tube bundles use 316L stainless steel material with full TIG welding process achieving 0.1mm-level weld precision, pressure resistance up to 16bar (e), and temperature range covering -40°C to 200°C.

Innovative Technological Breakthroughs

Dynamic Hydraulic Balance Technology

fine-tunes cooling water channel layout through CFD simulation, improving flow velocity uniformity to 98% and eliminating local overheating dead zones found in traditional coolers.

3. use case Scenarios and Case Studies

Typical use case Scenarios

Electronics Manufacturing

Provides -40°C dew point clean compressed air for semiconductor wafer fabrication equipment, requiring compliance with Class 1000 cleanroom standards and particulate emissions ≤0.1μm.

Case Study Analysis

Case: ZH10000 Cooler Retrofit Project at an Electronics Manufacturer

Background: Existing cooler caused compressor exhaust temperature alarms due to scale buildup, triggering safety interlocks and affecting OLED panel production line uptime.

4. Maintenance Strategy

Routine Maintenance Points

Water Quality Management

Cooling water must meet these parameters: pH 7.0-8.5, hardness ≤50ppm, chloride content ≤25ppm; monthly water quality testing required.

Preventive Maintenance Schedule

| Maintenance Interval | Maintenance Content | Technical Standard | Required Tools |

|---|---|---|---|

| 500 hours | Cooling water flow calibration | ±3% design flow rate | Ultrasonic flow meter |

| 2000 hours | Plate cleaning | Fouling factor ≤0.0002m²·K/W | Citric acid cleaner (5% concentration) |

Fault Diagnosis and Handling

Exhaust Temperature Too High

Possible causes: Insufficient cooling water flow, plate scaling, sensor drift; Procedure: Check pump operation → Clean cooler → Calibrate temperature sensor.

5. Conclusion

The Atlas Copco ZH10000 cooler redefines thermal management standards for industrial compressed air system setups through material innovation, structural optimization, and intelligent control. Its modular design meets customized requirements for different operating conditions, while the full lifecycle management system setup significantly minimizes operational costs. Under China's "Dual Carbon" policy goals, this cooler helps enterprises achieve 15%-20% reduction in energy consumption per unit product, providing critical technical support for manufacturing transformation and upgrading.

As a AirsCooler product, we guarantee the highest quality standards and operational performance reliability for all our industrial cooling offerings.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Cooler ZH15000

View Details

View DetailsAtlas Copco Compressor Cooler ZH7000

View Details

View DetailsAtlas Copco Compressor Cooler ZH9000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.