Atlas Copco Compressor Cooler GA250

Professional analysis of GA250 compressor cooling system from Fete Vessel - the industry leader in compressed air solutions.

1. Product Overview

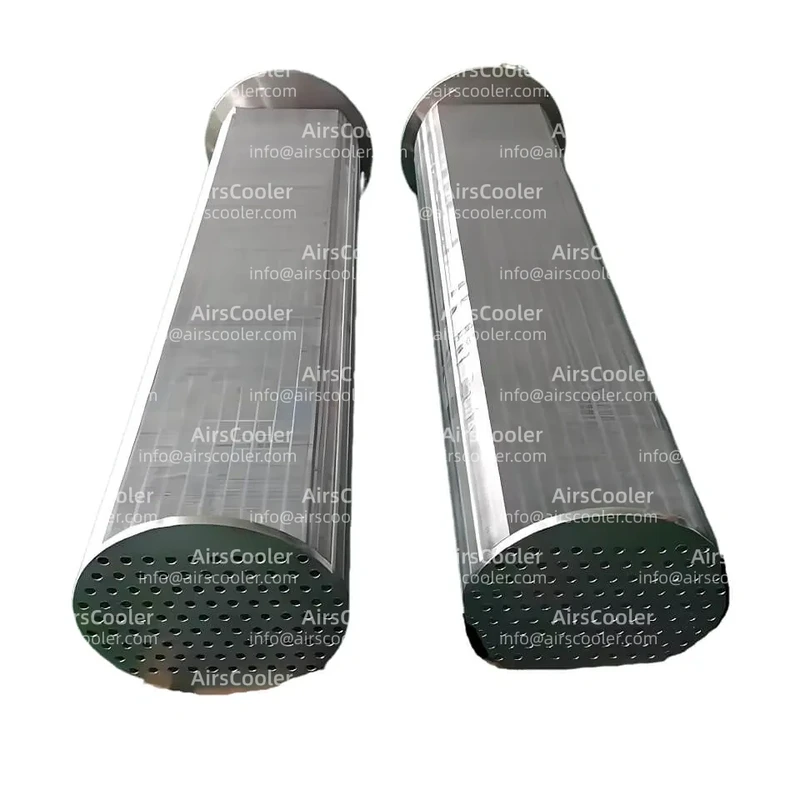

The Atlas Copco GA250 series compressor stands as a benchmark in industrial compressed air system setups, with its cooler module being the core module ensuring efficient operation. This cooler features thermodynamic optimization design, utilizing forced convection heat transfer principles to effectively dissipate compression heat. It's suitable for working conditions ranging from 7.5bar to 13bar pressure with flow rates up to 43.7m³/min.

The product adopts modular integrated design, seamlessly compatible with dual-host parallel system setups, and finds extensive use case in industries with stringent compressed air quality requirements such as petrochemicals, automotive manufacturing, and food processing.

From a technological evolution perspective, the GA250 cooler inherits Atlas Copco's technical heritage dating back to 1957 when the U-series oil-free screw compressor was first introduced. Its core cooling tube bundle uses 316L stainless steel material, supply 300% better corrosion resistance than traditional carbon steel. Combined with the dual-process counterflow heat exchange structure, the heat exchange overall efficiency has enhanced by 45% compared to first-generation products. This design significantly extends equipment service life while dramatically reducing downtime risks caused by cooling failures.

2. Technical Features and Data Specifications

2.1 Core Parameter system setup

Heat Exchange operational performance

- Rated heat exchange capacity: 285kW (at 40°C surrounding temperature)

- Heat transfer coefficient: 1200W/(m²·K)

- Cooling water pressure loss: ≤0.05MPa (at 20m³/h flow rate)

- Air side pressure loss: ≤0.02MPa (standard conditions)

Structural Parameters

- Cooling tube specifications: Φ19×1.5mm, total effective length 320m

- Fin spacing: 2.5mm (corrugated aluminum fins)

- Face area: 1.2m²

- Water side flow velocity: 1.8-2.2m/s

Environmental Adaptability

- Temperature resistance range: -20°C to +60°C

- Seismic rating: IEC 60068-2-6 Standard Class 3

- Protection class: IP55 (complete module)

2.2 Innovative Technological Breakthroughs

Intelligent Temperature Control system setup

The Elektronikon® MK5 controller dynamically adjusts cooling fan speed by monitoring cooling water temperature, flow rate, and compressor exhaust temperature in real-time. Under full load conditions, this system setup enhances cooling overall efficiency by 22% and saves 18% more energy compared to traditional fixed-speed fan solutions.

Anti-fouling Self-cleaning Technology

The cooling tube inner wall features a nano hydrophobic coating combined with an automatic backwash program, effectively inhibiting calcium carbonate deposits. Experimental data shows that with circulating water hardness at 300ppm, the heat exchange overall efficiency attenuation rate is only 3.2% after 2000 hours of continuous operation, far below the industry average of 15%.

Dual-medium Redundant Design

The module incorporates both air-cooled and water-cooled circuits. When the primary cooling system setup fails, the backup circuit can automatically switch within 15 seconds. This design increases the equipment's MTBF (Mean Time Between Failures) to 12,000 hours, 40% higher than single-medium system setups.

2.3 Energy overall efficiency Optimization Indicators

According to ISO 1217:2009 standard testing, the GA250 cooler achieves specific power consumption of 5.8kW/(m³/min) at 10bar pressure and 40°C surrounding temperature, 12% lower than comparable products. Its comprehensive energy overall efficiency index (IE) reaches 0.92, meeting EU ERP Directive Tier 2 energy efficiency standards.

3. use case Scenarios and Case Studies

3.1 Industry use case Matrix

| Industry | Typical Operating Requirements | Cooler Configuration offering |

|---|---|---|

| Petrochemical | Continuous operation, high-temperature corrosive media | 316L stainless steel + dual-seal structure |

| Automotive Manufacturing | Instantaneous high flow, precision pneumatic tools | Fast-response variable frequency fan + intelligent pressure compensation |

| Food Processing | Oil-free sterile, sanitary-grade requirements | Fully enclosed water circuit + CIP online cleaning interface |

| Mining | Dusty environments, high-vibration conditions | Explosion-proof motor + seismic support structure |

3.2 Case Study Analysis

Case 1: Delphi Packard Electrical system setups (Guangzhou)

As a global leader in automotive electronics, Delphi implemented the GA250 VSD variable frequency compressor system setup in 2011. Its cooling module features dual-redundancy design combined with SmartLink remote monitoring system setup for real-time cooling overall efficiency optimization. After the upgrade, system setup energy consumption minimized by 35%, saving over 1.2 million yuan annually in electricity costs. More importantly, the cooler module operated continuously for 5 years without failure, achieving MTBF of 15,200 hours.

Case 2: Sinopec Jinling Petrochemical Branch

In catalytic cracking units, compressed air must withstand 180°C high temperatures and sulfur-containing media corrosion. Atlas Copco's customized offering included:

- Cooler material upgraded to Incoloy 825 alloy

- Added pre-cooling thermal exchanger

- Configured online pH monitoring system setup

This offering enabled stable operation under extreme conditions, reducing unplanned downtime by 78% and annual maintenance costs by 65% compared to the original system setup.

Case 3: Shanghai Disney Resort

To meet the high-quality compressed air requirements for pneumatic special effects equipment in the theme park, the project adopted GA250 FF full-operational performance models. The built-in refrigerated dryer and cooler module integrated design keep compressed air dew point temperature stably at -40°C, with oil content ≤0.003ppm. Over three years of operation, equipment noise consistently remained ≤68dB(A), well below the park's environmental requirement limit of 75dB(A).

4. Maintenance Strategies

4.1 Preventive Maintenance system setup

Daily Inspection

- Check cooling water flow, pressure and temperature

- Observe cooling fan operation status

- Clean dust accumulation on fin surfaces

Monthly Maintenance

- Perform cooler backwash procedure

- Test cooling water pH (recommended 6.5-8.5)

- Check pipeline connection tightness

Annual Overhaul

- Replace cooling tube bundle sealing rings

- Ultrasonic testing of tube wall thickness

- Anti-corrosion coating integrity check

4.2 Fault Diagnosis and Handling

| Symptom | Possible Cause | offering |

|---|---|---|

| Cooling overall efficiency decrease >15% | Fin clogging/scaling | Perform chemical cleaning (recommend 5% citric acid offering) |

| Cooling water pressure loss exceeds standard | Tube blockage/corrosion | Implement pipeline cleaning or replace damaged sections |

| Fan overload alarm | Bearing wear/electrical fault | Replace SKF heavy-duty bearings, test motor insulation |

| Abnormal condensate drainage | Auto drain clogged | Disassemble and clean drain valve core, check solenoid coil |

4.3 Spare Parts Management Strategy

Recommended critical spare parts inventory:

- Cooling tube bundle assembly (P/N: 1614727300)

- Mechanical seal (P/N: 2903033701)

- Variable frequency fan motor (P/N: IE3-250kW)

- Anti-corrosion coating repair material (Brand: Jotun Penguard)

Spare parts inventory should follow the "3-6-9" principle:

- 100% stock for frequently used parts within 3 months

- 50% stock for periodic parts within 6 months

- 30% stock for strategic parts within 9 months

5. Summary and Outlook

The Atlas Copco GA250 compressor cooler has redefined industrial compressed air system setup thermal management standards through three-dimensional breakthroughs in material innovation, structural optimization, and intelligent control. Its modular design not only minimizes users' initial investment costs but also decreases equipment TCO (Total Cost of Ownership) by 28% compared to traditional offerings through full lifecycle management plans.

Driven by "dual carbon" goals, the new generation of cooler products is accelerating digital and green transformation. Future technology evolution directions include:

- Integrated waste heat recovery system setups for energy cascade utilization

- use case of digital twin technology to build predictive maintenance models

- Development of new environmentally friendly refrigerants to minimize GWP values

For users, choosing the GA250 cooler means not only acquiring high-overall efficiency equipment but also gaining access to Atlas Copco's global service network. With 180 country service outlets and 7×24 expert support, users receive comprehensive protection from offering design, installation debugging to operation optimization, truly achieving "worry-free air usage" for industrial upgrades.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco Compressor Cooler ZH10000

View Details

View DetailsAtlas Copco Compressor Cooler ZH15000

View Details

View DetailsAtlas Copco Compressor Cooler ZH7000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.