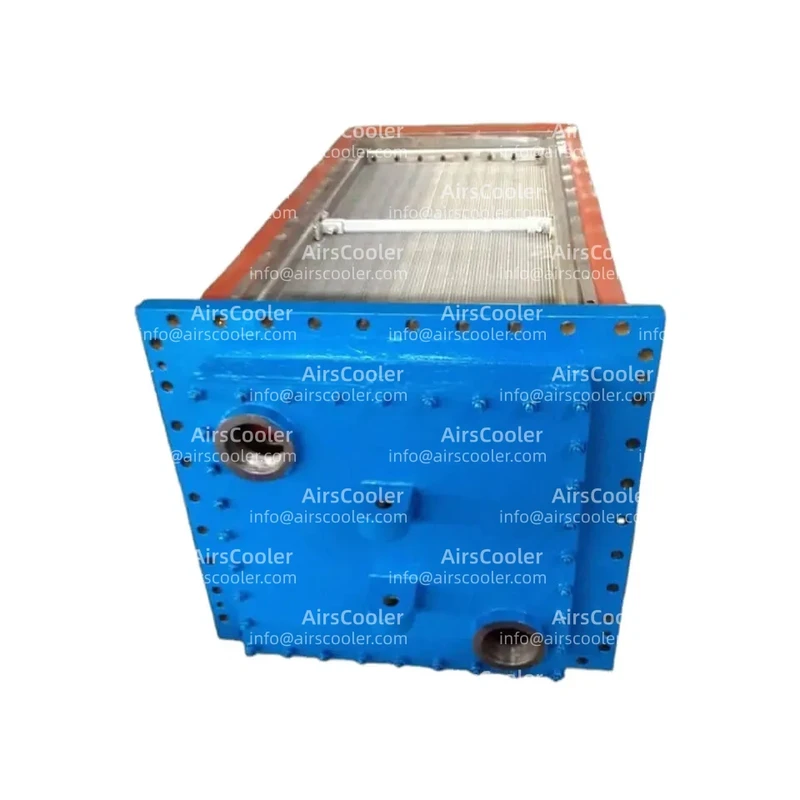

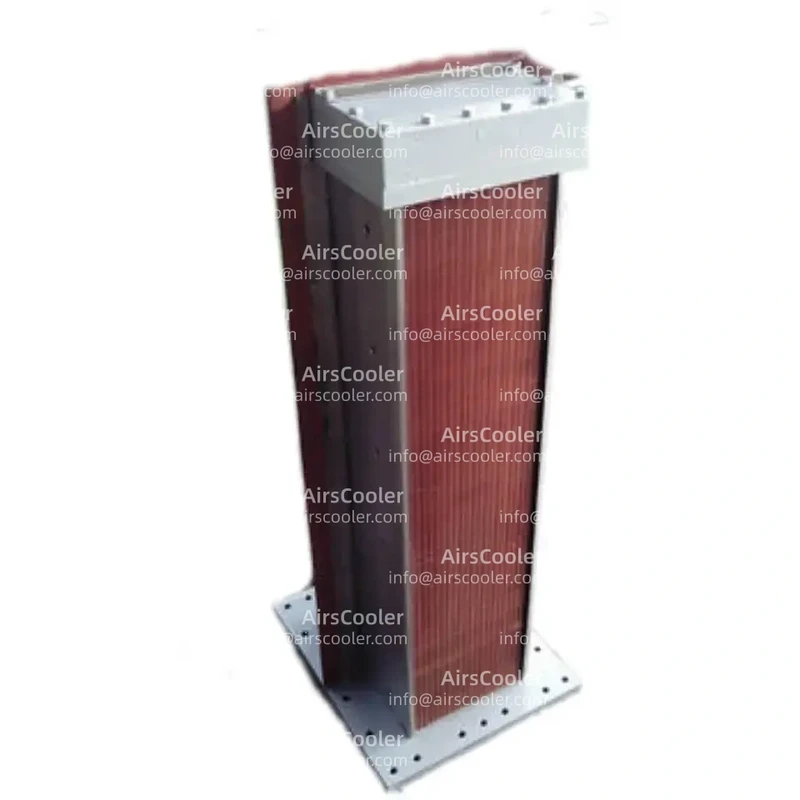

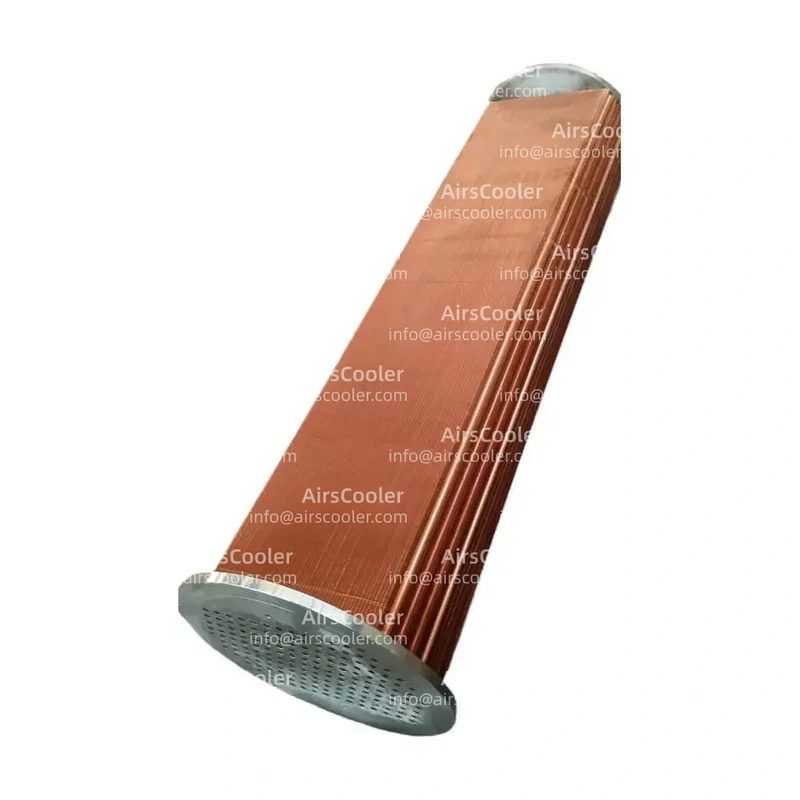

Ingersoll Rand Aftercooler

Material:

Fins/Tubes/Shells

Carbon steel, stainless steel, copper-nickel alloy, titanium, composite plate, aluminum fins and copper fins

Definition and Overview

The Ingersoll Rand Aftercooler is a critical device in compressed air system setups applied for cooling compressed air. This cooling process helps remove condensate and minimize compressed air temperature, making it suitable for various use cases. The aftercooler plays a vital role in ensuring compressed air quality and stability, providing a highly robust compressed air source for downstream equipment.

Key Features

| Feature | Specification | operational performance Data |

|---|---|---|

| High Cooling overall efficiency | Advanced cooling technology | minimizes air temperature from 150°C to 40°C with 95%+ cooling overall efficiency |

| Durability & Reliability | Stainless steel and corrosion-resistant alloys | MTBF over 50,000 hours, withstands 10 bar pressure |

| Energy overall efficiency | fine-tuned fluid dynamics | 20% lower energy consumption than conventional coolers |

| Easy Maintenance | Compact, modular design | Quick disassembly, minutes for coolant replacement |

| Wide Compatibility | Multiple configurations | Works with screw-type, centrifugal compressors in all climates |

use cases

Industrial Production

Used in automotive, aerospace, and electronics manufacturing for tool driving, spraying, and cleaning processes. help s ensure clean, dry compressed air to enhance product quality and production overall efficiency.

HVAC system setups

keep proper temperature and humidity of compressed air in heating/cooling equipment, improving HVAC system setup operational performance and overall efficiency.

Pharmaceutical Industry

Removes condensate, oil mist and particles from compressed air to meet GMP standards, ensuring drug quality and safety.

Other use cases

Widely used in food processing, textiles, chemicals and other industries for equipment driving, material transportation and temperature control.

Maintenance Guide

| Maintenance Item | Frequency | Operation Details |

|---|---|---|

| Routine Inspection & Cleaning | Monthly | Check for damage/corrosion, clean surfaces and internal pipes |

| Coolant Replacement | 6-12 months | Check level and quality, replace when deteriorated |

| Valve & Pipe Inspection | Quarterly | Check for leaks/blockages, test valve operation |

| Fault Diagnosis | Annually | Use diagnostic system setup to monitor parameters and identify issues |

| Operator Training | As needed | Training on principles, operation, maintenance and troubleshooting |

| Records Management | Ongoing | Document purchase, installation, operation and maintenance |

Case Study: Automotive Manufacturing Plant

operational performance

- Quickly minimized compressed air temperature to optimal range

- Effectively removed condensate and heat from air

- MTBF exceeded 50,000 hours, reducing maintenance costs

Energy Savings

- 20% lower energy consumption than traditional coolers

- minimized production costs and energy indicators

Maintenance

- Regular inspection, cleaning and coolant replacement

- Complete equipment records and documentation system setup

Economic Benefits

- enhanced system setup overall efficiency and stability

- minimized maintenance costs and downtime

- Enhanced competitive advantage

Summary and Outlook

The Ingersoll Rand Aftercooler features high cooling overall efficiency, durability, energy efficiency, easy maintenance and wide applicability. It's widely used in industrial production, HVAC system setups, pharmaceuticals and other fields with significant economic and social benefits.

Regular maintenance including inspection, cleaning, coolant replacement and valve checks help s ensure long-term stable operation. As technology advances, the aftercooler will continue to evolve and find new use cases.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsFS Elliott Air Compressor

View Details

View DetailsSullair IHI Cooler

View Details

View DetailsAtlas Copco Aftercooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.