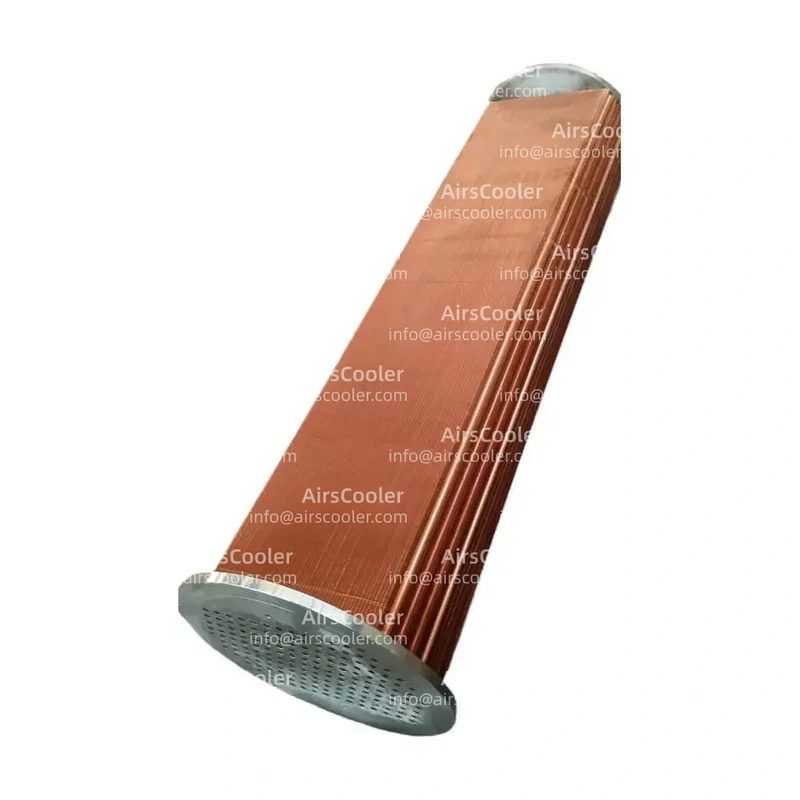

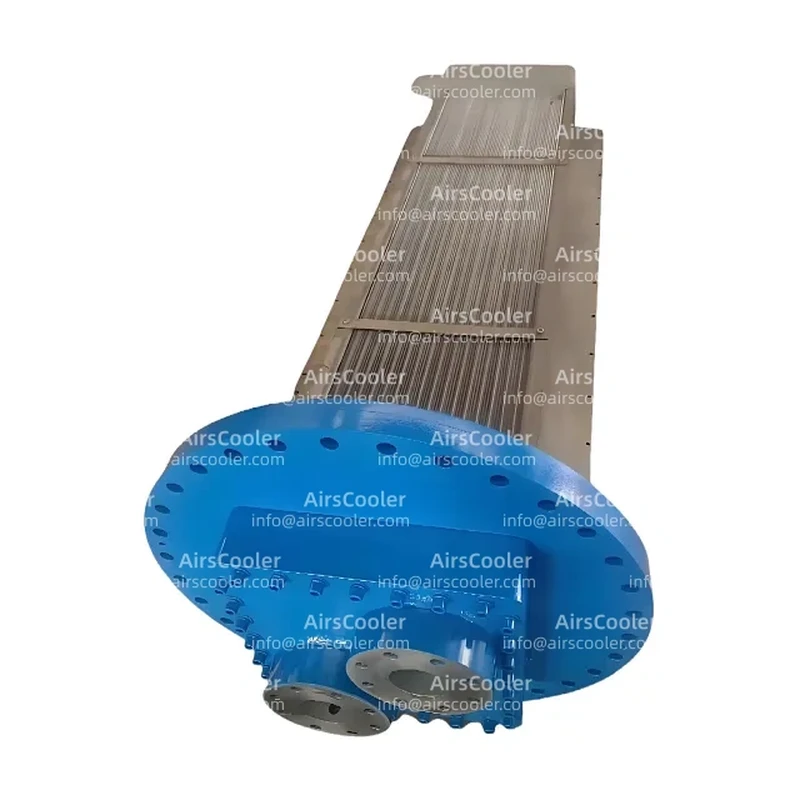

Atlas Copco Aftercooler

Product name: Atlas Copco air compressor After cooler

Applicable for Atlas Copco:

ZH6, ZH7000, ZH10000, ZH15000, HL6, HL8, HL9

ZR2, ZR3, ZR4, ZR5, ZR6.

ZR55, ZR75, ZR90, ZR110, ZR132, ZR145

ZR160, ZR200, ZR250, ZR275, ZR300,ZR315

ZR355, ZR400, ZR425, ZR450, ZR500, ZR630

ZR700, ZR750 ZR900

GA315, GA355, GA450, GA500

General Description

The Role of Atlas Copco Cooler:

Atlas Copco coolers, also known as thermal exchangers, are vital modules in air compressors. Depending on the medium applied for heat exchange, they can be classified into two types: water-cooled and air-cooled. To address the limitations that may arise from relying on external cooling water sources, these machines are often designed with integrated coolers. These coolers include water storage and cooling functions. This are commonly referred to as water tanks.

The primary function of the Atlas Copco cooler is to dissipate the heat generated during the air compressor's operation through a heat exchange process between the media. This process effectively minimizes the air compressor's operating temperature, ensuring optimal operational performance and prolonged operation of its main modules. Additionally, the cooler plays a crucial role in improving compressed air quality by condensing and discharging condensate from the saturated air, thus facilitating trouble-free operation.

Working Principle of Atlas Copco Cooler:

The flow of Atlas Copco air compressor oil is driven by the pressure differential within the system setup, moving from the separator tank to the central compressor. Initially, when the oil temperature is below 77℃, the temperature control valve remains closed, enableing the oil to pass directly through the oil filter without traversing the Atlas Copco cooler. Subsequently, as heat generated by the compression process is absorbed, the oil temperature gradually increases. Once the oil temperature surpasses 77°C (88 °C for the 24KT model), the temperature control valve opens, directing some of the oil to flow through the Sullair cooler before reaching the main engine via the oil filter.

Maintenance of Atlas Copco Cooler:

Regular maintenance of the Atlas Copco cooler is essential to help ensure its optimal operational performance. Accumulating oil, grease, dust, and dirt on the cooler's surface can impair heat exchange overall efficiency, resulting in excessive exhaust temperatures. Therefore, cleaning the outer surface of the cooler every two weeks using a vacuum cleaner, cleaning fluid, or low-pressure compressed air is recommended. Additionally, it is crucial to frequently discharge the condensed water from the aftercooler in environments with low surrounding temperatures or high humidity. In particular, when the temperature drops below 0°C, daily draining of the aftercooler's condensed water is necessary.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsSamsung Compressor Intercooler Aftercooler

View Details

View DetailsIngersoll Compressor Rand Cooler

View Details

View DetailsFS Compressor Cooler

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.