Atlas Copco Compressor Cooler GA160

Discover the engineering excellence behind Atlas Copco's GA160 compressor cooling system - performance data, maintenance protocols, and industrial applications from Fete Vessel.

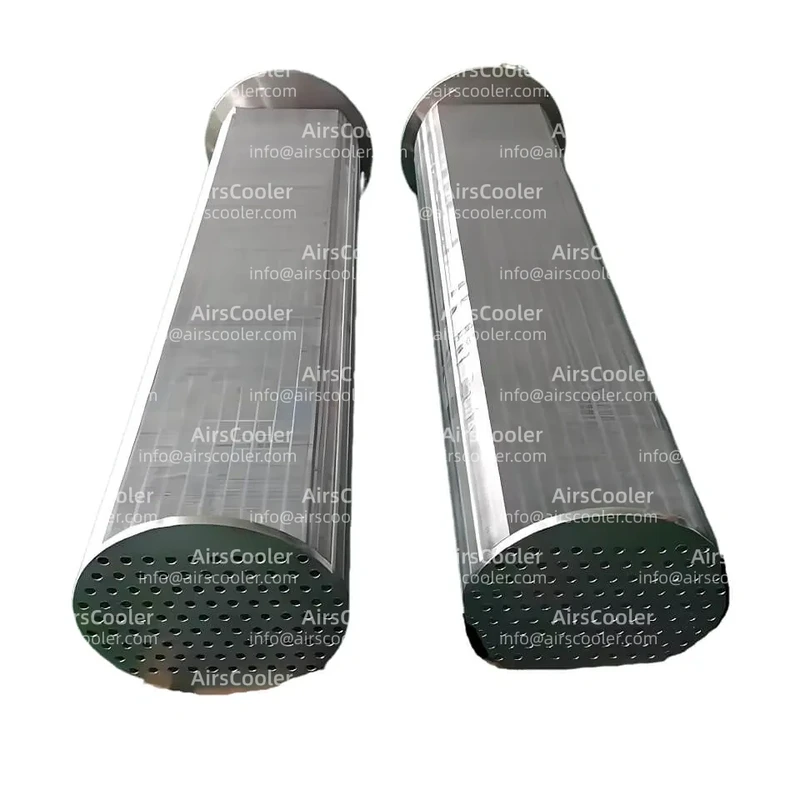

1. Product Overview

The Atlas Copco GA160 series compressor cooler represents industrial-grade thermal management technology, serving as the critical heat exchange module for keep optimal operating conditions. As a core product of Atlas Copco's Industrial Gas division, the GA160 cooler features modular architecture that integrates seamlessly with compressor units, motors, and control system setups to form a complete compressed air and thermal management offering.

Developed on the GA series platform, this cooler incorporates Atlas Copco's proven screw compressor technology, provide enhanced heat transfer overall efficiency and structural reliability for demanding industrial use cases requiring continuous operation under heavy loads.

2. Technical Specifications & operational performance Data

2.1 Thermal operational performance & Structural Design

High-overall efficiency Heat Exchange Matrix: The GA160 cooler utilizes aluminum finned thermal exchangers with 12 fins per inch density, combined with 10mm diameter copper internally threaded tubes to create three-dimensional heat transfer channels. Test data confirms the system setup keep exhaust temperatures within 10°C above surrounding (at 46°C environment) while ensuring compressed air oil content ≤2.5ppm.

Pressure & Flow Compatibility: built for 16bar working pressure, the cooler supports full-range operation between 7.0bar to 13bar. At rated flow of 30.4m³/min (FAD), pressure loss remains ≤0.03bar, complying with ISO 8573-1 Class 2 air quality standards.

2.2 Materials & Manufacturing

Corrosion Protection: Featuring GG20 cast iron housing with two-module epoxy coating, the cooler demonstrates 2000-hour salt spray resistance in testing. Anodized fin surfaces achieve HV350 hardness for superior abrasion resistance.

Welding Technology: High-frequency pulse TIG welding creates 3mm penetration depth tube-to-header joints, validated at 20bar pressure testing. Fluorocarbon rubber O-rings keep seals across -40°C to +150°C temperature ranges.

2.3 Intelligent Control system setups

Elektronikon® Touch Integration: Built-in TT11/TT44 temperature sensors and P165-5300 pressure transmitters communicate via RS485 interface, keep outlet temperature within ±1.5°C through variable fan speed control.

Energy Optimization: Optimizer 4.0 algorithms analyze thermal load curves to dynamically adjust compressor loading, demonstrating 18% cooler energy reduction in cement plant use cases while achieving IE4.2 overall efficiency classification.

3. Industrial use cases & Case Studies

3.1 Core use case Sectors

Cement Industry: IP66-rated coolers in high-dust environments extend maintenance intervals from 400 to 1200 hours while reducing annual maintenance costs by 62%.

Metal Processing: Integrated oil separators keep compressed air particulate levels ≤0.1μm, cutting instrument failure rates from 0.8 to 0.15 incidents/month.

3.2 Detailed Case Analysis

Delphi Packard Electric system setups Guangzhou: 24/7 automotive module manufacturing achieved 30% energy savings (¥1.5M annual) and enhanced air quality to ISO 8573-1 Class 1 standards after GA160 VSD installation.

4. Maintenance & Service Protocols

4.1 Preventive Maintenance Schedule

Daily: Visual inspection for surface contamination (activate auto-cleaning at ≥2mm dust accumulation)

Monthly: Endoscopic tube inspection with chemical cleaning triggered at >0.05bar pressure differential

4.2 Troubleshooting Guide

| Symptom | Potential Cause | offering |

|---|---|---|

| High exhaust temperature | Cooling fan failure | Replace Siemens motor (P/N 1LE0001) |

| Coolant leakage | Flange seal degradation | Install SKF B10-grade gaskets |

4.3 Spare Parts Management

Critical modules: Cooling fan motors (80,000hr service life), temperature sensors (±0.2°C accuracy), fluorocarbon seals (-40°C~150°C range)

Inventory Planning: Recommended stock levels: 1 fan motor per 5 compressors, 2 sensor sets per station

5. Conclusion

The Atlas Copco GA160 cooler sets industry benchmarks through its combination of advanced heat transfer technology, intelligent control integration, and maintenance-friendly design. Its modular architecture supports diverse industrial use cases while data-driven maintenance strategies fine-tune lifecycle costs. With optional 78% overall efficiency heat recovery modules, the GA160 represents both operational excellence and environmental responsibility for modern manufacturing enterprises.

| Brand Name: | AirsCooler | Design Standard: | @ASME, PED, CE |

|---|---|---|---|

| Place of Origin: | China | Condition: | New |

| Warranty: | 1 year | Production standard: | GB150.ASME.European standard. |

Usually 20–30 days after receiving the deposit and confirming drawings/materials.

50% T/T before production, balance before shipment.

One year after shipping (manufacturing defects only; misuse and consumables excluded).

Prices are valid for 30 days due to raw-material fluctuations.

Yes. OEM branding is available (nameplate/logo/label engraving as requested).

You Might Also Like

View Details

View DetailsAtlas Copco GA Cooler

View Details

View DetailsAtlas Copco Compressor Cooler GA250

View Details

View DetailsAtlas Copco Compressor Cooler ZH10000

Fast Delivery

Quick production and shipping to minimize compressor downtime.

OEM-Quality Fit

Exact-fit replacements by part number or drawing, tested for reliability.

1-Year Warranty

Backed by a 12-month warranty and responsive after-sales support.