Samsung TM1250 Centrifugal Air Compressor — Complete Specs, Controls & Anti‑Surge Guide

Project & Model Overview

The Samsung (Hanwha) TM1250 is a three‑stage, integrally‑geared centrifugal compressor supplied as a complete oil‑free air package. Each unit delivers about 180 m³/min at 1.0 MPa(G), with closed‑loop cooling water and PLC‑based control, including coolers, blow‑off and silencer.

Key Performance & Site Conditions

Rated flow 180 m³/min (at suction), discharge pressure 1.0 MPa(G), discharge temperature ≤ 42 °C. Reference ambient 30 °C, 68% RH. Cooling‑water inlet ≤ 30 °C with ~8 °C rise; total water usage around 112 t/h.

Drive & Power

TECO 6 kV, 50 Hz induction motor, approx. 1,111 kW (service factor 1.15), IP23, class‑F insulation with class‑B rise, nominal speed ~2970 rpm. Journal bearings with forced lubrication; bearing and stator temperature monitoring.

Compressor Core & Materials

Three 17‑4PH stainless‑steel impellers (115% over‑speed tested and dynamically balanced), integral machined diffusers, labyrinth gas and oil seals, horizontal split gearcase (GCD400). Helical gears to AGMA 13; alloy steels (SCM440/SACM645) carburized and ground.

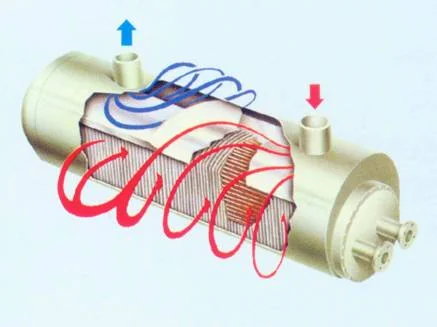

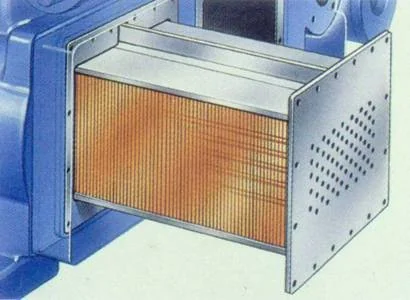

Cooling & Moisture Separation

Intercoolers are shell‑and‑tube with water on the tube side; copper tubes with anti‑corrosion fin treatment. Each stage includes a moisture separator and auto drain. Lube oil is cooled via a shell‑and‑tube cooler; oil grades like Shell T‑32/Mobil DTE Light are typical.

Lubrication System

Integrated oil tank with level gauge/low‑level alarm; main IMO screw pump driven by the gearbox, auxiliary electric gear pump (NOP) for start/stop and coast‑down cooling; a thermostatic mixing valve stabilizes oil temperature; an immersed heater preheats oil before start. Normal bearing supply ~0.17–0.21 MPa(G).

Control Philosophy

Two operating modes: constant‑pressure and automatic. Inlet guide vanes (IGV) modulate flow to hold pressure, and the blow‑off valve opens at the unload set‑point to avoid surge. Anti‑surge logic tracks ambient‑driven surge‑line shifts. Platform: PLC + 5.7" HMI (Chinese UI supported), MODBUS RS485/RS232 for DCS.

Protections, Alarms & Monitoring

Interlocks cover high temperature, low oil pressure, surge detection, vibration by impeller end, motor current, sensor failures and I/O diagnostics. The HMI provides trending, run/loaded hours, alarm history and maintenance reminders.

Mechanical Interface & Standards

Process connections per ASME B16.5 with matching flanges supplied. Design and testing reference API 672, ASME PTC‑10, AGMA, NEMA/IEC and internal MS. Sound pressure near the package ≤ 85 ± 3 dBA at 1 m height and distance.

Guarantees & Service

Oil‑free discharge guaranteed; continuous operation up to ~60 °C ambient. Key consumables target ≥ 8,000 h life. Warranty: 18 months from shipment or 12 months after commissioning (whichever occurs first), with local service and spares.