Ingersoll Rand Centrifugal Air Compressors Overview and Operation

What This Course Covers

Introduction to Ingersoll Rand centrifugal air compressors for industrial plants: how they work, the main components, operation and maintenance, selection criteria and configuration, and market outlook with efficiency trends.

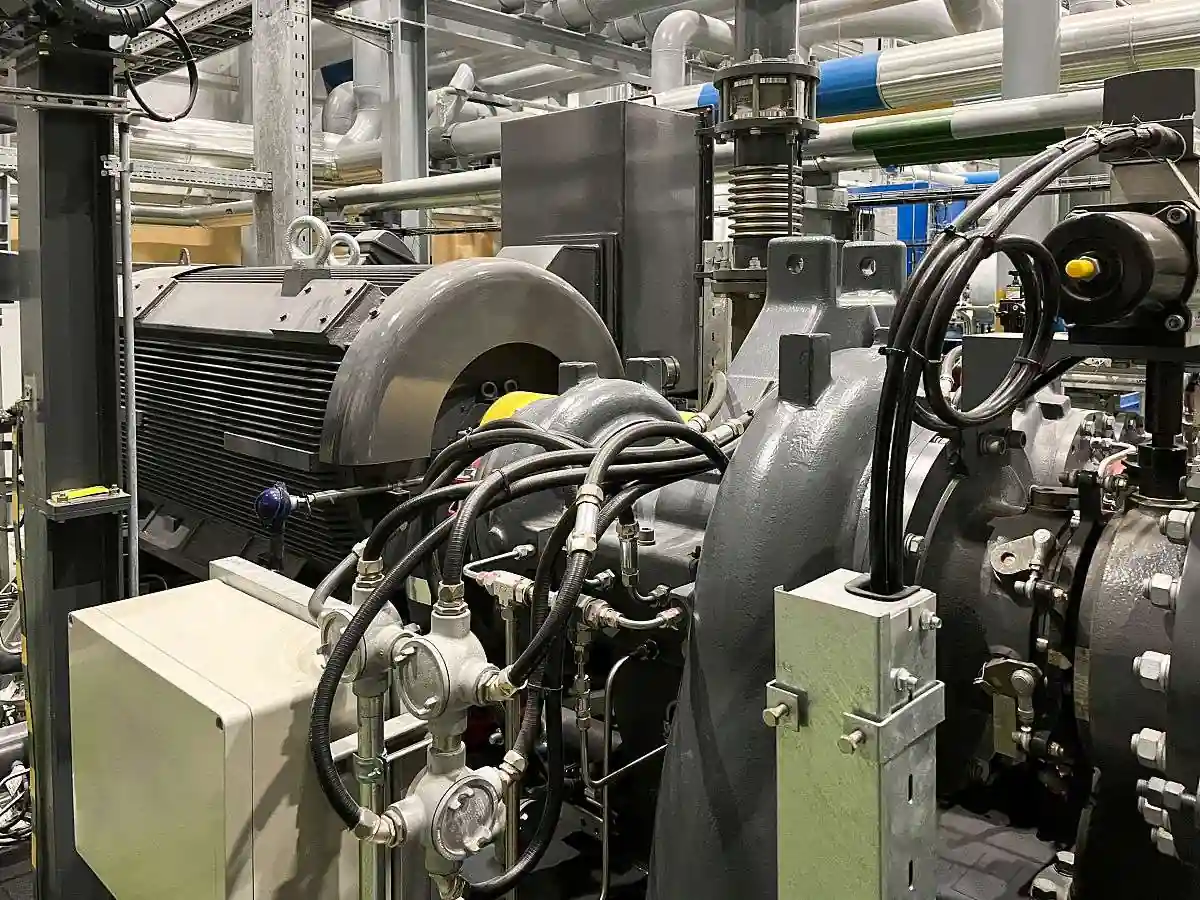

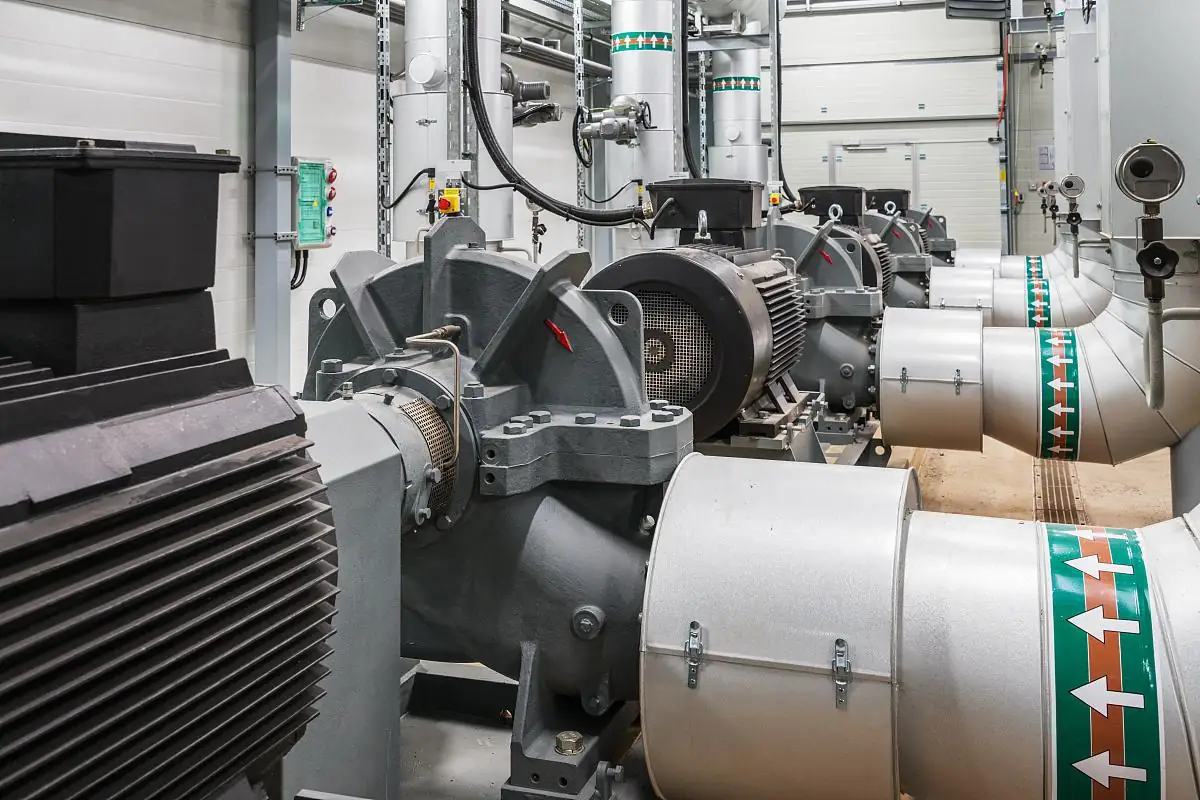

Working Principle

A rotating impeller accelerates air; the diffuser converts velocity to pressure. Multi‑stage compression with intercooling raises pressure efficiently, delivering smooth flow, low pulsation and reliable continuous duty compared with reciprocating machines.

Key Features and Benefits

High efficiency from advanced impeller and flow‑control design; low noise with engineered enclosures; long life by optimized materials and processes; modular construction that simplifies service; and stable pressure control for critical users.

Operation and Maintenance

Before start: check lube‑oil level/temperature, cooling‑water flow and inlet filters; confirm rotation and permissives. During operation: monitor pressure, temperature and vibration; verify IGV/BV positions and condensate drains. For shutdown: unload (IGV 0%, BV 100%), stop, run auxiliary lube for cool‑down, drain separators and bundles.

Troubleshooting Quick List

• Pressure anomaly: inspect inlet/NRV/BV and pressure controls.

• High temperature: check cooling‑water flow/temperature, clean coolers.

• Excess vibration: review alignment, coupling and bearing condition.

• Abnormal noise: inspect loose internals or rubbing; verify filters and valves.

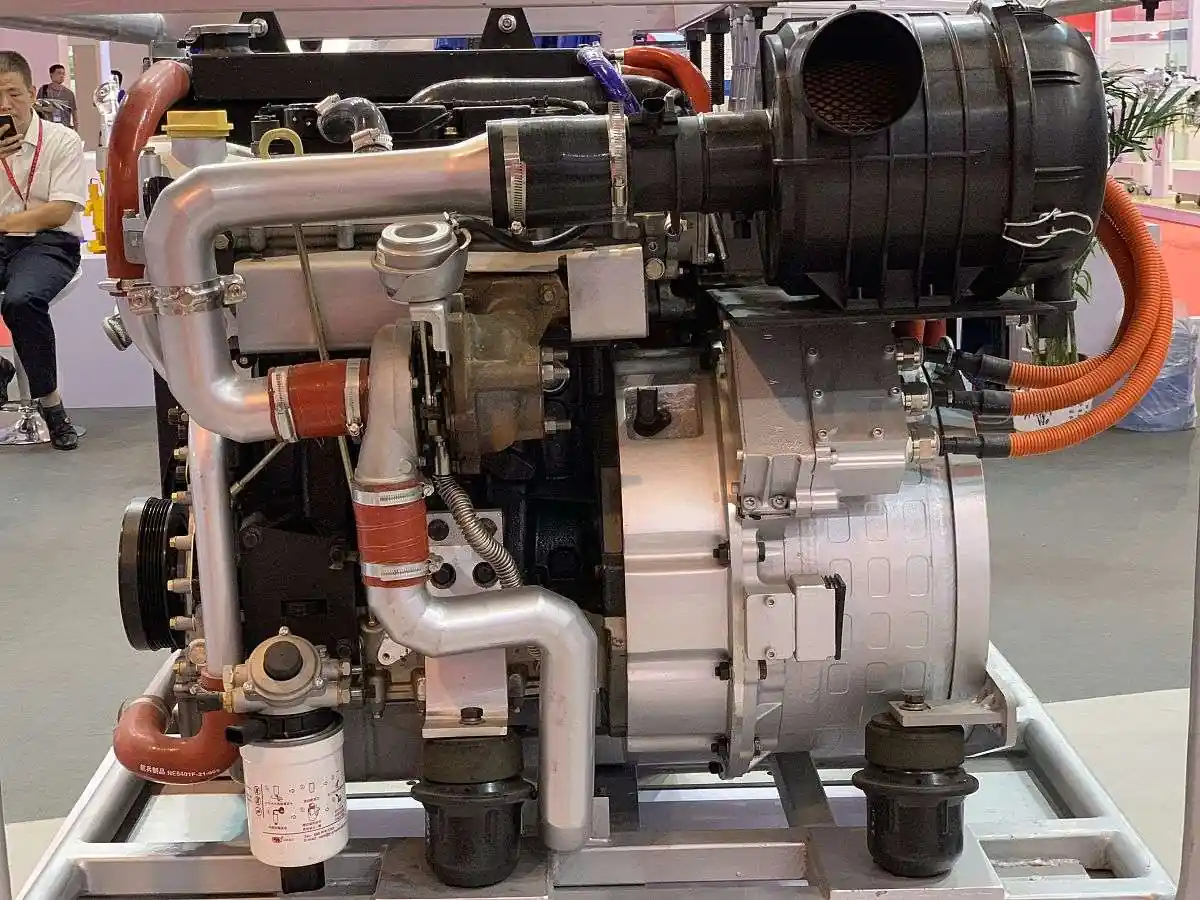

Selection and Configuration

Match flow and pressure to plant demand; specify air‑quality targets and treatment; consider lifecycle cost (CAPEX + OPEX). Core subsystems include the compressor core, cooling system, and intelligent controls for remote monitoring and diagnostics.

Performance Metrics

Flow (Nm³/h or CFM), pressure (bar g), efficiency (wire‑to‑air), and reliability. Proper IGV tuning, clean inlet filtration and clean heat exchangers preserve efficiency and stability across seasons.

AirsCooler Solutions

AirsCooler supplies OEM‑fit intercoolers, aftercoolers and replacement bundles for IR centrifugal platforms, supporting retrofits and upgrades with materials such as stainless steel and CuNi to reduce ∆P and strengthen corrosion resistance.