Centrifugal vs Screw Air Compressors Pros Cons and Selection Guide

What This Guide Covers

This article compares centrifugal and oil‑injected screw air compressors across efficiency, flow/pressure capability, footprint and noise, maintenance and reliability, CAPEX/OPEX, and the best‑fit applications.

Efficiency & Flow

Centrifugal compressors excel in high‑flow duty with strong wire‑to‑air efficiency at design point. Oil‑injected screws are efficient at small‑to‑medium flows and part‑load with VSD. Turndown comes from IGV/bleed (centrifugal) versus speed/slide‑valve control (screw).

Pressure Capability & Controls

Screws handle broad pressure ranges and fast pressure response; centrifugal machines favor stable pressures around a set design. Anti‑surge logic plus IGV/blow‑off protects centrifugal cores; screws rely on VSD/slide‑valve and bypass for stability.

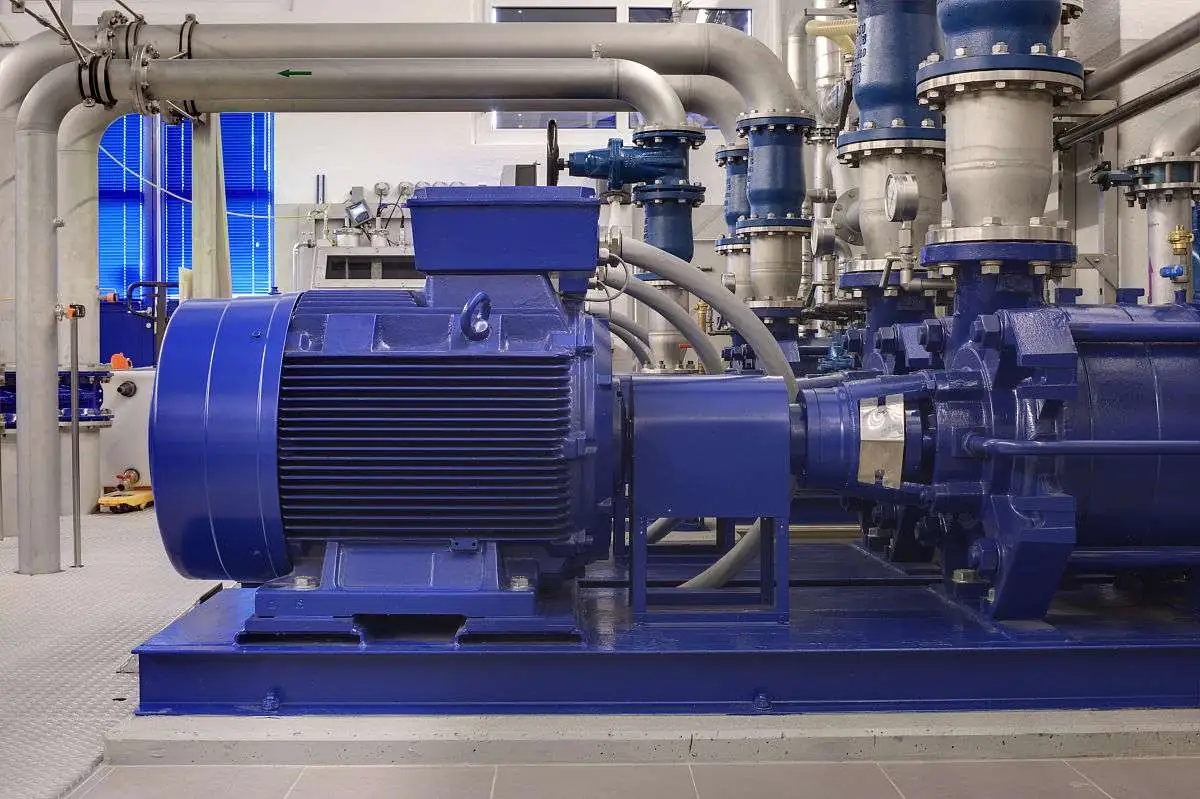

Footprint, Noise & Installation

Screws are compact and easy to place, often quieter at low ratings; centrifugal packages grow with duty but consolidate large flows. Noise enclosures and low‑loss ducting benefit both types.

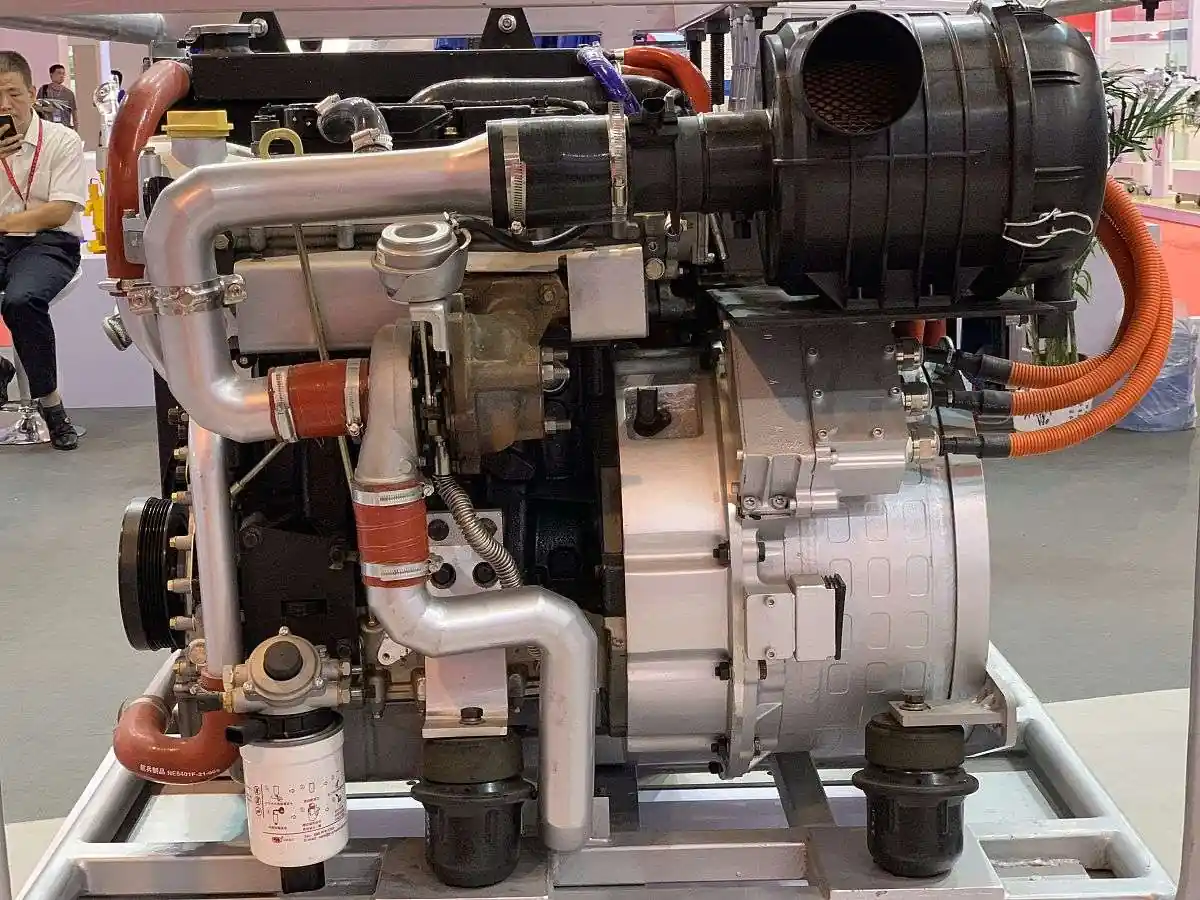

Maintenance & Reliability

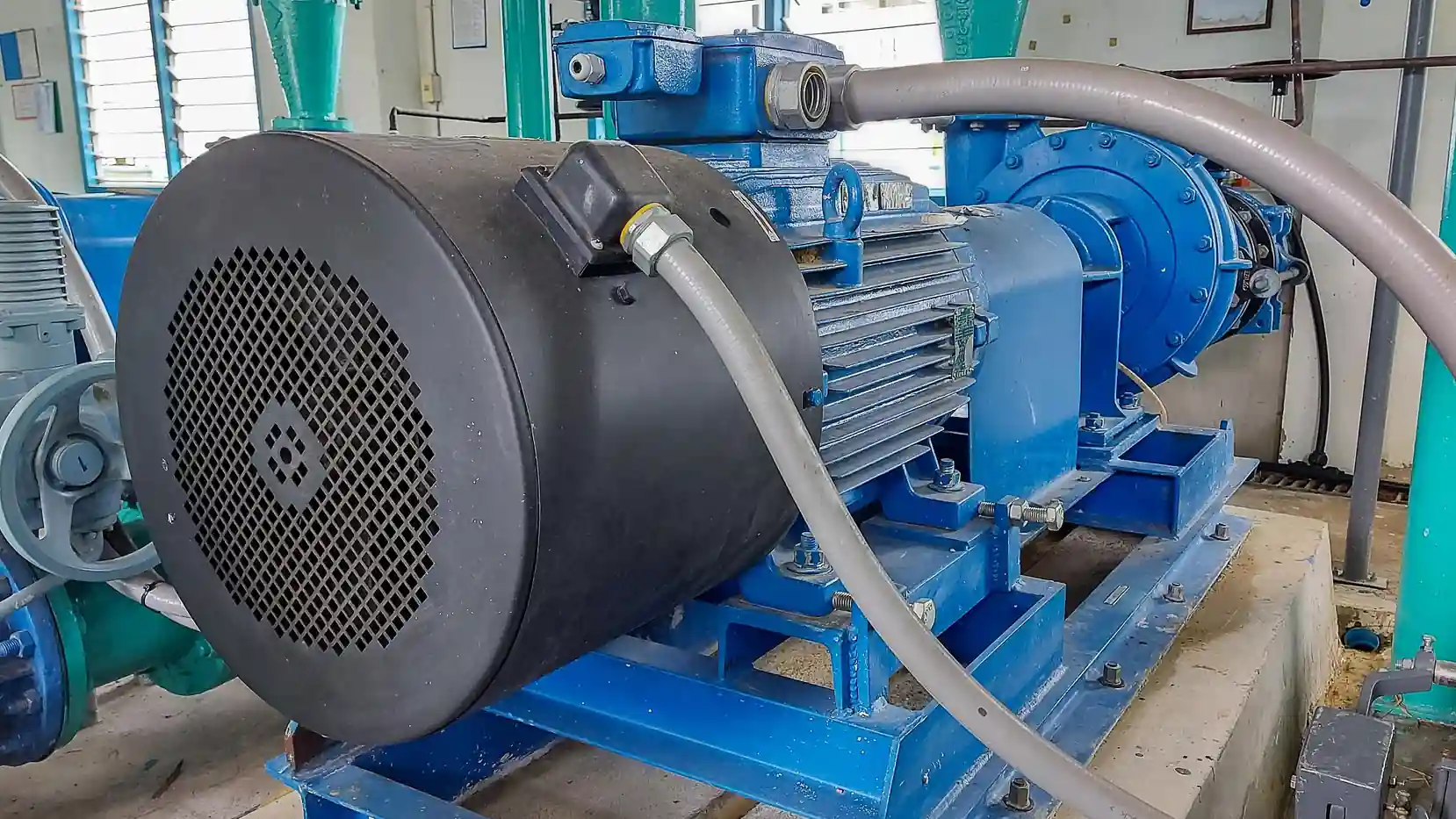

Centrifugal units have fewer wearing parts (no contact rotors) and long service intervals; their main tasks are filter, cooler and bearing/lube care. Screws need oil, separators, and air‑end overhauls at defined hours, but offer straightforward service.

CAPEX & OPEX

Screws typically have lower initial CAPEX at small/medium flow; centrifugal packages deliver attractive OPEX in high‑flow plants thanks to aerodynamics and fewer consumables. Careful life‑cycle analysis is essential.

Applications & Best Fit

Choose centrifugal for steel, glass, chemicals, electronics and other large, steady air demands. Choose screws for distributed loads, frequent starts/stops, or wide pressure/flow variability in smaller plants.

Selection Checklist

• Flow profile and future growth

• Required pressure/stability and events (start/stop, spikes)

• Ambient and cooling utilities (air vs water)

• Maintenance windows, local service, spare parts

• Total cost of ownership (CAPEX + OPEX + downtime)

AirsCooler Solutions

AirsCooler supplies intercoolers/aftercoolers and custom heat‑exchanger bundles for both centrifugal and screw packages, supporting OEM replacements and retrofits with short lead times.