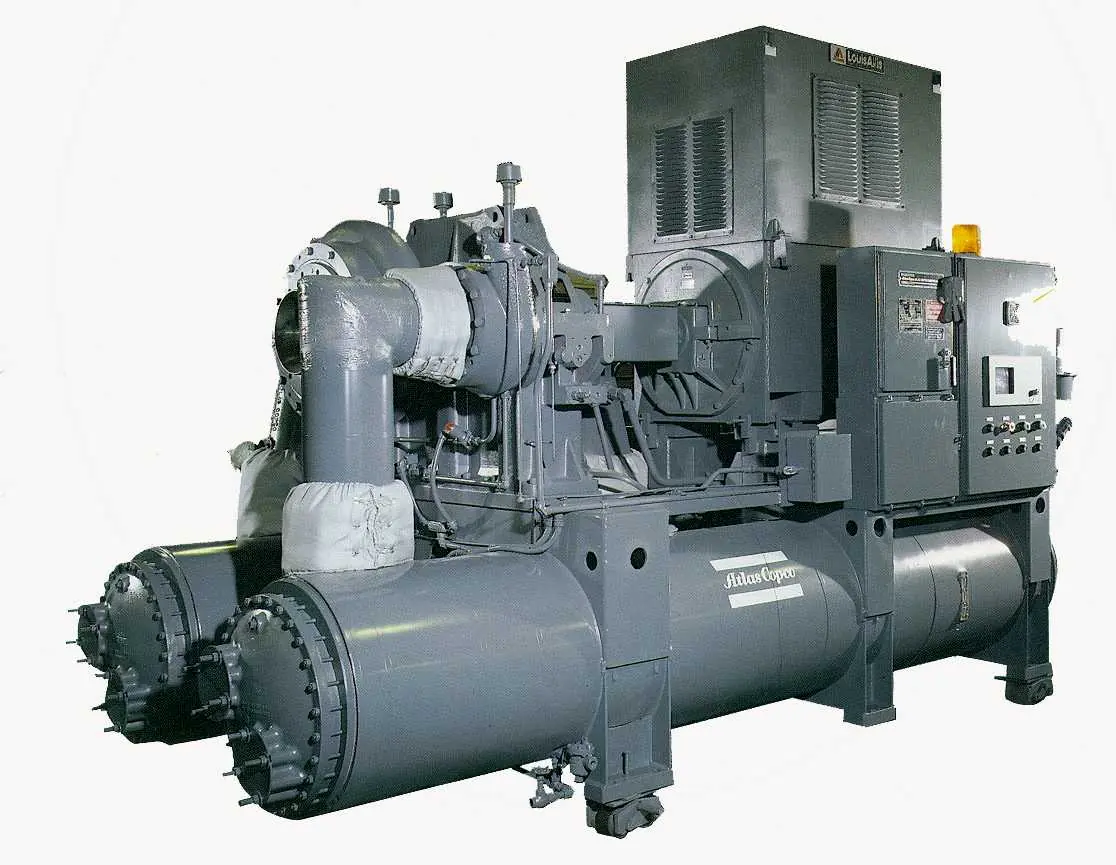

Atlas Copco ZH Oil-Free Centrifugal Compressors Overview

ZH Series Overview

Atlas Copco’s ZH series are skid‑mounted, oil‑free, integrally‑geared centrifugal compressors supplied as complete packages. Models such as ZH7000, ZH10000 and ZH15000 cover large flows with low noise and ISO9001‑backed quality.

Integrated Package & Enclosure Options

Factory‑piped and tested packages reduce site work: connect discharge, two cooling‑water lines and power to run. Optional noise enclosure further lowers SPL while keeping service access. Responsibility is clear and installation cost is minimized.

Air Path, IGV Control & Blow‑Off

High‑efficiency inlet filters (up to 99.9% coarse / 99.5% fine) protect the core. Inlet guide vanes (IGV) modulate flow to maintain pressure with significant power savings versus butterfly‑valve throttling. Electric blow‑off actuators require no instrument air and integrate silencers, simplifying layout.

Impellers, Diffusers & Gearing

Back‑swept 3D impellers in Armco 17‑4PH stainless undergo 115% over‑speed and dynamic balance. Segmented diffusers cut loss and raise stage efficiency. Micro‑spline impeller connections transmit up to ~10,000 kW and speed service. Helical gears to AGMA Q13, rotors fully balanced per API 672 practices.

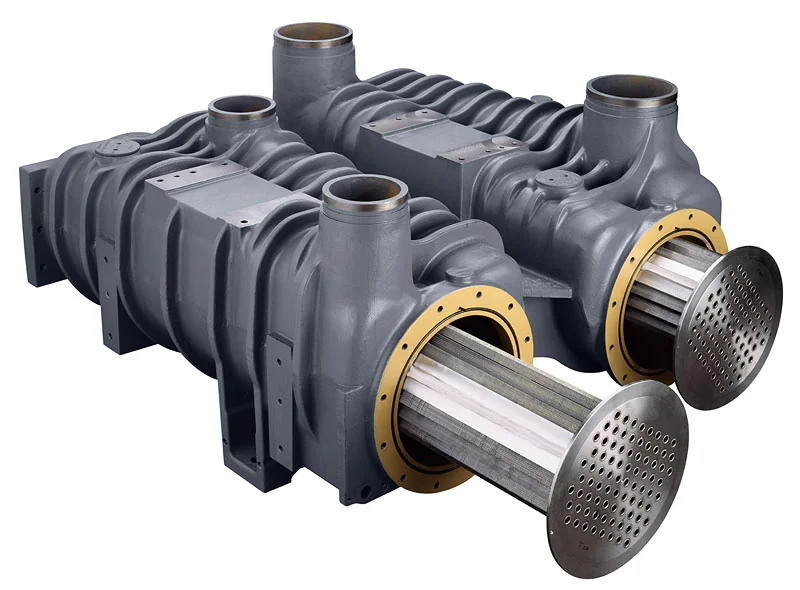

Inter/Aftercoolers & Moisture Separation

Shell‑and‑tube intercoolers/aftercoolers use corrosion‑resistant construction; covers open from both ends for easy cleaning. Labyrinth‑type demisters and auto‑drains remove condensate with >99% efficiency, reducing carryover and fouling.

Lubrication System

All‑welded oil tank with inspection ports, immersion heater, thermostatic valve, full‑flow oil cooler and filters. Main over‑flow pump on the gearbox and an electric auxiliary pump secure lubrication during start/stop and power loss.

Drive & Motor Options

High‑quality ABB or Siemens motors, typically 3000 rpm (2‑pole), medium‑voltage (3–10 kV), class‑F insulation, class‑B rise, IP23/IP55 protection, service factor 1.15. Disc coupling requires no routine maintenance.

Controls, Anti‑Surge & Communications

The controller shows all running parameters, set‑points, alarms and trips; it modulates flow and protects against surge. Surge prediction uses Δp measurements at the second‑stage nozzle. Communications include Modbus/Profibus/Ethernet for DCS integration.

Reliability & Maintenance

Carbon‑ring gas seals and labyrinth oil seals minimize leakage. Horizontally split gearbox and tilting‑pad bearings improve stability and make inspection quick—gear checks in ~2.5 h.

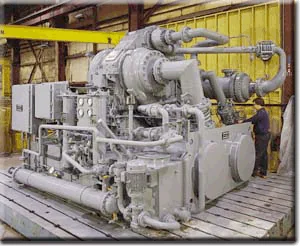

Applications & Footprint

The ZH series serves steel, chemicals, glass, electronics, textiles and automotive plants. Packages offer high rigidity, short piping and aerodynamically optimized connections for low pressure drop and high efficiency.