Air Compressor Waste Heat Recovery Principles and Applications

Why Recover Waste Heat from Compressors?

During continuous operation, air compressors convert electrical energy to mechanical energy, then to compressed air—with ~60% of input power appearing as heat in the oil/air stream and cooler surfaces. Temperatures typically reach 80–100 °C, and most of this energy is otherwise rejected to ambient via the cooling system.

Basic Principle

Route hot compressor oil (or discharge air) through a heat exchanger and transfer energy into water. With city‑water at ~5–20 °C, outlet hot‑water temperatures of ~60–75 °C are common, while maintaining oil return at ~55–65 °C.

Typical System Layout

A skid with a plate or shell‑and‑tube exchanger, a circulation tank, level/temperature control, and a delivery pump. When set temperature is reached, hot water is delivered to a storage tank for later use (e.g., shift‑end showers or process).

Economics vs. Conventional Heating

Compared with electric or fuel‑fired water heating—or even solar—waste‑heat recovery has near‑zero running cost. For a 500‑person facility using ~10 t/day of hot water (electricity ¥0.9/kWh example), annual operating savings can be significant.

Heat Exchanger Options

• Plate heat exchangers: compact, high U‑value; widely used for oil‑to‑water duty.

• Double‑pipe exchangers: simple, high pressure capability; modular area; suited to smaller flows.

• Heat‑pipe exchangers: use phase change to move heat from hot zone to cold zone efficiently.

Air‑ vs Water‑Cooled Packages

Both air‑ and water‑cooled compressors can support recovery; water‑cooled packages simplify water‑to‑water transfer, while air‑cooled units may leverage ducted air‑to‑water coils or heat‑pump assistance.

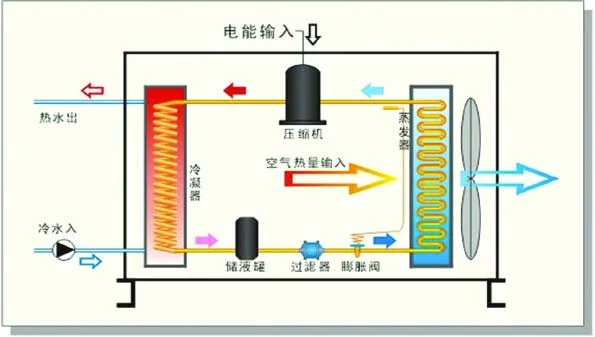

Heat Pump Enhancement (Optional)

A heat pump lifts heat from a lower to a higher temperature level (reverse‑Carnot cycle). It can boost outlet water temperature or extend recovery under cold ambient conditions when air‑cooled packages struggle.

Industrial Hot‑Water Uses

Process rinsing/cleaning (electrophoretic paint, can washing), textile dyeing/finishing (30–90 °C), electronics/semiconductor ultrapure‑water heating, and boiler make‑up preheat—plus staff sanitary hot water.

Project Data to Survey

Identify water type (domestic/process/boiler return), daily volume and headcount, distance from compressor room to use points, compressor count/rating/cooling mode, and present heating method to estimate ROI and design scope.

Design & Controls Notes

Maintain compressor oil temperature limits; include auto drains and demisters on the water side, and interlocks for low flow/over‑temperature. Ensure access for cleaning of plate or shell‑and‑tube bundles; plan for seasonal temperature variation.